|

javabug

|

|

« on: July 29, 2012, 20:12:54 pm » |

|

Had a significant high-rpm miss since putting the 010 into service. I put new points in this year, supposed to have the stronger spring to prevent "floating" (not sure I buy that concept). Welp, still laying over really bad above 5k rpm. So I put my modified German 009 back in, and it rips smoothly up to 7k.

It's just weird the 010 is failing me this way. I can't think of anything that would cause it. Interestingly, my 019 acted the same way on this motor.

|

|

|

|

|

Logged

Logged

|

Mike H.

Sven was right.

|

|

|

|

glenn

|

|

« Reply #1 on: July 29, 2012, 21:45:35 pm » |

|

Weird, cause i've my my 010 well into the 7000rpm range with no problem. My Sun machine goes up to 6000rpm and i've never had a problem. Both Bosch and Bremi points work fine.

Are you using the same points and condenser on the 010 and 019? It's really odd that 2 sets would have the same miss.

<a href="http://www.youtube.com/v/9u8ddB1zL38" target="_blank">http://www.youtube.com/v/9u8ddB1zL38</a>

|

|

|

|

« Last Edit: July 29, 2012, 21:48:43 pm by glenn »

|

Logged

Logged

|

|

|

|

|

javabug

|

|

« Reply #2 on: July 29, 2012, 22:12:25 pm » |

|

Are you using the same points and condenser on the 010 and 019? It's really odd that 2 sets would have the same miss.

No, they're the 356 points (I think) that you sent me over the winter. I was hoping they'd cure that. |

|

|

|

|

Logged

Logged

|

Mike H.

Sven was right.

|

|

|

|

glenn

|

|

« Reply #3 on: July 29, 2012, 22:16:35 pm » |

|

Must be the Bremi since Bosch stopped making them. I've sold hundreds and never a problem. I did once have a weird miss that drove me crazy. Then i found my tach wire was chaffed and sometimes would cause my points to ground and ... miss. Make sure the metal clip on the points bolt is not touching or near the contact plate. That can cause a miss since it grounds and the points will look closed.  |

|

|

|

« Last Edit: July 29, 2012, 23:10:26 pm by glenn »

|

Logged

Logged

|

|

|

|

|

javabug

|

|

« Reply #4 on: July 29, 2012, 22:57:16 pm » |

|

I've tried paying attention to that area, because I always seem to have trouble keeping the bolt from grounding out. Even put a small piece of shrink wrap on the bolt where it passes through. I'll have another look.

|

|

|

|

|

Logged

Logged

|

Mike H.

Sven was right.

|

|

|

|

glenn

|

|

« Reply #5 on: July 29, 2012, 23:08:00 pm » |

|

The hole in the square insulator is offset so if you have it the "right" way the 2 prongs on the metal clip will wrap around and will prevent if from turning and grounding to the contact plate.

|

|

|

|

« Last Edit: July 29, 2012, 23:10:45 pm by glenn »

|

Logged

Logged

|

|

|

|

|

181

|

|

« Reply #6 on: July 30, 2012, 14:54:09 pm » |

|

my engine with 010 and Bremi 356 points went regularly to 6500 rpm with no hassles :-)

|

|

|

|

|

Logged

Logged

|

|

|

|

|

bugnut68

|

|

« Reply #7 on: July 30, 2012, 16:49:26 pm » |

|

Quick question, and be easy on me in case this is a really dumb question: why not go with a pointless module over points? That's one of the upgrades I've had no regrets doing with my 009s as I hate gapping points. I'm no longer in the group of driving VWs over long distances, but if I did, I'd certainly keep a condenser and points in my tool box as a back up, but I've never had any issues with the Pertronix or Compufire modules failing.

Seems like this would be an easy solution to avoiding floating points.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Mike Maize

|

|

« Reply #8 on: July 30, 2012, 17:23:37 pm » |

|

Maybe it is the gravity in PA or something?  My points always floated in my 67, until I got my Pertronix set up, now it is buttery smooth and the points are in a bag just in case.... |

|

|

|

|

Logged

Logged

|

|

|

|

|

|

|

javabug

|

|

« Reply #10 on: July 30, 2012, 19:20:31 pm » |

|

why not go with a pointless module over points? You cut off the path of ideation and go beyond thinking and escape from emotional consiousness, to reach a clear, open state of freedom that sweeps all before it. — Yuanwu (1063-1135) I do it for the Zen. |

|

|

|

|

Logged

Logged

|

Mike H.

Sven was right.

|

|

|

|

TiDi

|

|

« Reply #11 on: July 30, 2012, 23:38:24 pm » |

|

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Cheesepanzer

|

|

« Reply #12 on: July 31, 2012, 00:07:54 am » |

|

Years ago when I was trying to get more RPM out of my 009 I added a second spring to the points from an old points. The thin spring laid right over the other. Was able to rev the 009 well into 8000 rpms when I was only able to get about 7 out of the stock set. You might consider trying to add a second spring to the 010 points. I believe any spring from a set of 009/010 Bosch points will work.

|

|

|

|

|

Logged

Logged

|

62 Beetle (street/strip build)

63 Type 2 Single Cab

Cornpanzers

|

|

|

|

glenn

|

|

« Reply #13 on: July 31, 2012, 00:23:21 am » |

|

Here's my observation of Pertronix. the 1844 used to fit but 3 years ago I had to enlarge the hole for the brass pin to pass through. I send Pertronix customer support pictures with measurements and they told me to continue making the hole larger until they fixed it. 2 years later is was not fixed. I also found on a few that the magnets were not exactly 90* apart so you can have a difference of a few degrees across the cylinders. The 6v can miss when there's low voltage, so driving with the headlights and wipers on can cause problems. I've seen 6 of them fail in the past 2 years and they just drop dead with no warning. As for points, i've gotten over 20,000 miles on a set. And you can always get gone if there's a problem. |

|

|

|

|

Logged

Logged

|

|

|

|

|

TiDi

|

|

« Reply #14 on: July 31, 2012, 10:19:41 am » |

|

Thank you Glenn really appreciate it !  |

|

|

|

|

Logged

Logged

|

|

|

|

|

glenn

|

|

« Reply #15 on: July 31, 2012, 11:19:16 am » |

|

Thank you Glenn really appreciate it !  Glad to help, after all I do know a few things about the Bosch 010  |

|

|

|

|

Logged

Logged

|

|

|

|

|

Bruce

|

|

« Reply #16 on: August 01, 2012, 17:05:02 pm » |

|

It's just weird the 010 is failing me this way........, my 019 acted the same way on this motor. Describe your distributor clamp bracket. Is it painted? |

|

|

|

|

Logged

Logged

|

|

|

|

|

javabug

|

|

« Reply #17 on: August 01, 2012, 19:00:42 pm » |

|

Bare metal, possibly plated at one time. Some oily fingerprints. M6 stud and a nut to tighten. OEM, of course.

|

|

|

|

|

Logged

Logged

|

Mike H.

Sven was right.

|

|

|

|

hotrodsurplus

|

|

« Reply #18 on: August 05, 2012, 01:22:37 am » |

|

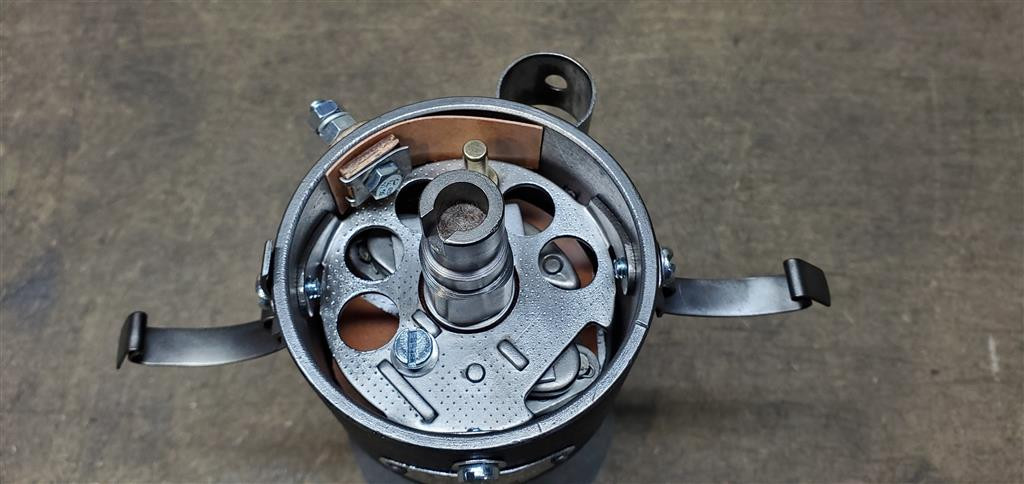

There. I fixed it.  [ Attachment: You are not allowed to view attachments ] |

|

|

|

|

Logged

Logged

|

Chris Shelton. Professional liar.

|

|

|

|

javabug

|

|

« Reply #19 on: August 05, 2012, 22:27:57 pm » |

|

That would be MAG-nificent!  I don't know if a mag would look right with Dell'ortos. |

|

|

|

|

Logged

Logged

|

Mike H.

Sven was right.

|

|

|

|

hotrodsurplus

|

|

« Reply #20 on: August 05, 2012, 23:00:38 pm » |

|

I don't know if a mag would look right with Dell'ortos.

Yeah, I'd be afraid of the fashion police too.  |

|

|

|

|

Logged

Logged

|

Chris Shelton. Professional liar.

|

|

|

|

glenn

|

|

« Reply #21 on: August 05, 2012, 23:46:38 pm » |

|

A mag from and industrial engine would not have a performance curve.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

hotrodsurplus

|

|

« Reply #22 on: August 06, 2012, 04:32:38 am » |

|

A mag from and industrial engine would not have a performance curve.

True but the only difference between a mag from an industrial engine and a mag with a performance advance curve is a set of advance plates. That's an everyday thing. But no factory Volkswagen distributor has a true performance advance curve. Some are just close for a good number of engines if you're not that critical. You gotta tune all of 'em to match an engine's specific needs. Actually, the curve plate on the industrial mag that I have would work beautifully for a real hot-cammed/high compression engine: 16 degrees all in by 1,800rpm. The curve on my Hunt-prepped tach-drive mag is actually lazier: 20 degrees in by 2,000. And just so I don't get jumped on, I'm not really suggesting Mike run a magneto. |

|

|

|

|

Logged

Logged

|

Chris Shelton. Professional liar.

|

|

|

|

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge