I alway seem to have one popping and coughing at times.

Popping through the intake indicates a lean condition. The three most common causes for lean conditions are vacuum leaks, plugged idle jets, and float settings.

People have their favorite ways to find vacuum leaks but the most reliable way I've found is to push a hose over the end of a propane torch, open the valve, and point the tip at the potential leak points while the engine is running. Others like carb cleaner but it attacks paint and isn't always reliable.

DCN-series carburetors are especially vulnerable to plugged idle jets. They originally came with 'stacks' cast into the carb top. They serve as velocity stacks but they also extend the float-bowl opening above the filter floor. Unfortunately they usually get milled off to run aftermarket air filters. Despite their popularity those oiled cotton-gauze filter elements do a terrible job at filtering dirt big enough to clog an idle jet.

A low float setting usually causes a lean condition in higher-speed transition. Think WOT.

I pulled the spark plugs and the spark plugs have a good brownish tip to them.

The term tip, while commonly used, doesn't indicate a specific place. It's better to define the actual parts. You have a ground strap, electrode, porcelain, and base ring. Each of those will tell you more about how the engine runs. The following link explains how to read a plug. Bear in mind that water-cooled engines can usually tolerate leaner conditions than air-cooled Volkswagens. So what's perfect for an ACVW might be pig rich for a water-cooled car.

http://www.wallaceracing.com/plug-reading-lm.htmlI think my trouble is getting the air beed screws set properally.

Okay, for clarification there are no air-bleed screws. There are air-bleed jets but those have a fixed orifice and come in different sizes.

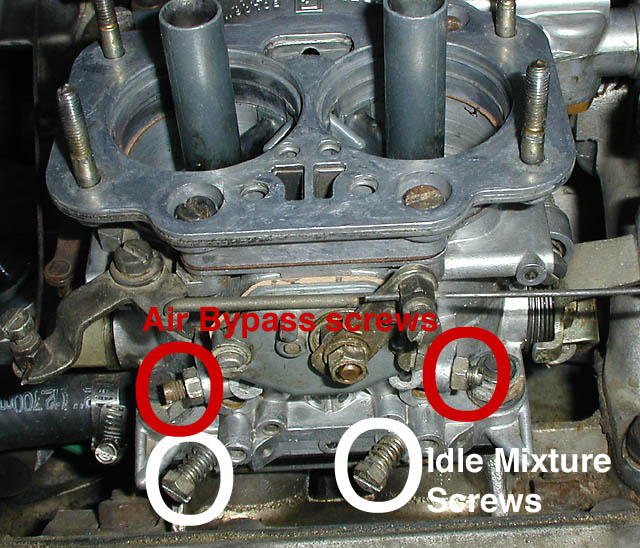

Do you mean the air-fuel mixture screws or do you mean the air-bypass screws? Here's an image that shows them:

In crude terms the air-bypass screws exist for applications where you'd have to open the throttle blades sufficiently to uncover the progression ports just to get the engine to idle properly. In those cases you'd close the throttle blades enough to cover the progression ports then open the bypasses enough to give the engine the air it needed to idle (the idle port would still administer idle fuel). Most tuners recommend closing those air bypasses altogether.

The air-fuel mixture screws are another story. There are tons of instructions on how to set them properly so I won't go there. But if they're set too lean then the respective cylinder will run poorly at idle. Mixture-screw setting doesn't have much bearing on engine dynamics once the progression ports start opening (tipping into the throttle).

(carb's were set up by Clyde Berg many years ago. Car isn't driven much, weekend cruiser).

This could be a big contributor to your problem. If the engine was tuned prior to the ethanol-enhanced fuels then it's likely too lean now. Stoichiometry of old-world gasoline was 14.7:1 but the ethanol-enhanced fuels have a stoic of about 14:1. So the carburetors may require larger idle-fuel and main-fuel jets.

But before you start changing parts willy-nilly take the time to eliminate the other variables. If it were mine I'd pull the carburetors and replace the manifold-to-head gaskets. Do the same for the carb-to-base gaskets if they're rough. It wouldn't hurt to just go through the carburetors with new kits. Make sure the floats are set right.

FWIW, there's a debate as to how to set float heights when using ethanol-enhanced fuel. Because ethanol has greater density than gasoline the float will actually sit higher in ethanol-based fuel therefore the fuel level will drop. In theory at least. In application the percentages are so small that it probably doesn't make a difference so I wouldn't actually deviate from the specs. However, I'd set the floats on the higher side (closer to the lid) of the acceptable range just to be on the safe side.

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge