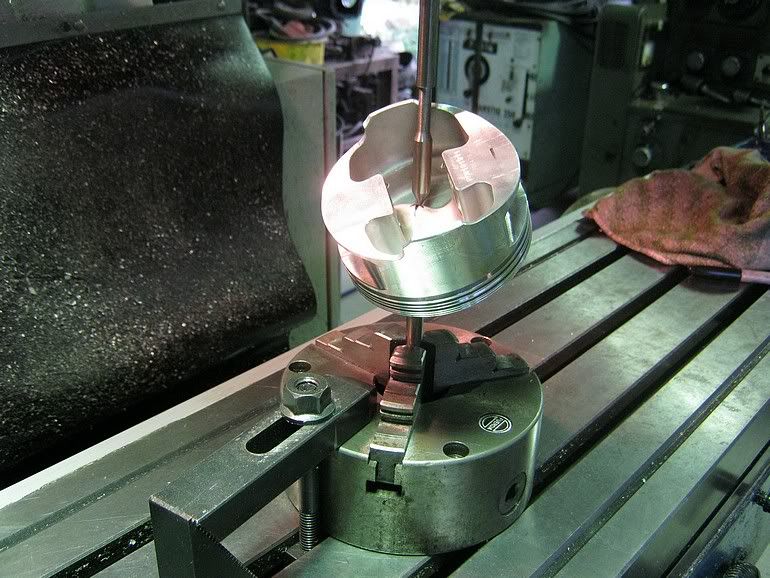

I would not "knowingly" fit a piston with a hole like that,

but I have disassembled a perfectly perfoming engine that had 'holed' there.

Since then I only notch to as deep as the first land is high,

and ALWAYS USE A RADIUS IN THAT LOCATION!!

I also set up a simple tool to measure the minimum thickness in other parts of the piston.

The way that notch has been done, it is likely that a piece will break away at some point,

so best would be start with a new set.

If you need more piston to valve clearance there are many other ways.

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge