Time for a bit of an update as it really is overdue.

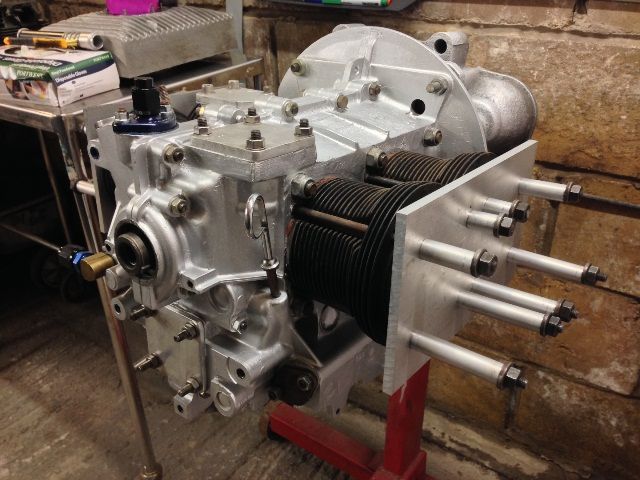

Turning my attention to the motor first, something I always hated about the engine was dull finish of the case due to oxidisation. It just didn’t look right with all the work I’d done on the rest of the car. Thus I decided to paint it using engine enamel.

I'm really pleased with the final results.

Yes I know there is much debate about painting cases, but it done now so well see.........(n.b. heads removed so that the manifolds can be match ported)

Despite a long wait, work has also begun on the body as well.

To recap (my UK friends might remember that annoying phrase from Beetle Crisis!) the body was delivered to Double H Restorations last year (the boys at Double H have a long waiting list), but it has finally began to get some love.

Now although I’d trial fitted the doors I’d always knew they’d need some adjustment as they were tight at the B pillars and were not even all the way down.

Using a panel gap gauge Nick of Double H Restorations measured the gap at the B pillars. They definitely needed some adjustment. :-s

In the end we tried a couple of different doors to see if it was the doors, or the body, that was out of shape. It turned out that all the doors fitted pretty much the same, and thus we decided it was the body that would be adjusted.

I had actually got some genuine 59 doors by this point. It had always bugged me that the door I had initially used were slightly later door (60-63), thus it was decided that we would use the 59 doors even though they had a few dents and dings in them. I must be nuts as the 60-63 doors were new old stock!!

However the 59 doors would need to be adjusted as well, as they also did not fit great down the B pillar. In the end Nick awesome metal work skills saved the day with him actually slitting the edge of the B pillars and moving these in order to set the gap. Although this sounds drastic it allowed the alignment on both doors to be set perfectly.

The body was then mounted on a roll over jig so the underside could be checked out. Sadly a few patches of rust were found.

Both rear body mounts needed some work. Although the passenger side was repaired by lettings in some fresh steel in, the driver’s side was going to need some more substantial repair work.

A repair panel was sourced, but the quality of this was poor with it being very different from the original panel. The shock tower hole was square not round, and the body mount was a very poor copy of the original.

However, a spot on reproduction of the original mount was sourced from Hooky's Panel Shop, with Nick sectioning the new and the old panels together.

And here's the repaired panel. Massive thanks to Nick for all his attention to detail. It is impossible to tell that the panel has been repaired at all.

The carpet grip strips on the heater channels were also looking a bit worse for wear.

Once removed a whole lot of rust was found behind the strips.

Luckily the rust cleaned away nicely leaving solid metal. Nick again saved the day by hand fabricated new carpet grip strips as none are available for early cars. Thanks again dude.

Once the doors were fitted and the repair work was completed Nick began to strip the paint off the body. Luckily most of the outer panels were pretty solid.

Work has also begun on the other panels. The bonnet has been blasted, filled and primered.

Both the vert and standard decklids have also been fillered and primered. Really pleased with the vert decklid, as it was in really bad shape when I first got it.

The wings are also now in primer.

As are many of the smaller parts.

So that’s where the car is at the moment.

Hopefully more updates soon.

Dude

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge