|

red baron

|

|

« on: January 19, 2011, 18:43:02 pm » |

|

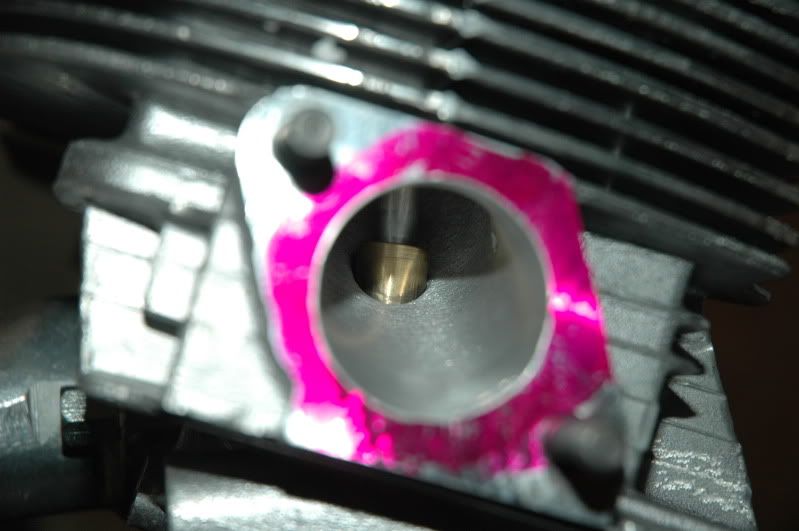

Hey guys, I thought I'd show you what I did last summer and maybe it gives me some motivation too, to work on it again. here is just the spec's: VW AS21 case DPR 78.4 crank Mahle 90.5 DRD L5 043 heads Engle W125 Weber 44idf Thorsten Pieper lifters Schadeck 30mm pump Full Flow and all case plugs were out Scat 1:1.25 rockers Scat flywheel Kennedy stage 1 Cushion grip disc GB Pushrods Udo Becker polished con rods however - here some picture. It started with a vague idea how an engine could be look like. first an old case which got refurbished at engine plus, germany a crank from DPR:  and later a pair of heads with some old carbs for test fitting   First mock up pictures   then about a year after the first parts arrived I went on (inbetween I had to study) This is the fun part, where a friend and I decided to assemble the crakshaft late at night.     This action caused a little fotoshooting for the german VW Speed Magazine:  -> Product Placement!    More pictures will follow |

|

|

|

|

Logged

Logged

|

|

|

|

|

|

|

red baron

|

|

« Reply #2 on: January 19, 2011, 20:01:23 pm » |

|

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Harry/FDK

|

|

« Reply #3 on: January 20, 2011, 18:27:43 pm » |

|

Did you bake that case in the KITCHEN oven ?

|

|

|

|

|

Logged

Logged

|

Done ? Not Yet.

|

|

|

|

red baron

|

|

« Reply #4 on: January 21, 2011, 15:17:04 pm » |

|

The nice and expensive fittings arrived    The oil sump extension  Udo Becker rods...just perfect  the shop  Rods and pistons get the all the same weight  and then everything is ready to start the assembly  |

|

|

|

|

Logged

Logged

|

|

|

|

|

Jesse/DVK

|

|

« Reply #5 on: January 21, 2011, 16:54:36 pm » |

|

Looks very nice! Is that the temperature sender located next to the oilpump?

|

|

|

|

|

Logged

Logged

|

Der Vollgas Kreuzers

|

|

|

|

red baron

|

|

« Reply #6 on: January 21, 2011, 17:44:09 pm » |

|

Yes that's the temperature sender

|

|

|

|

|

Logged

Logged

|

|

|

|

|

fredy66

|

|

« Reply #7 on: January 22, 2011, 12:03:39 pm » |

|

I'm Reading keep the photos coming

|

|

|

|

|

Logged

Logged

|

arabia slugs

|

|

|

|

|

|

red baron

|

|

« Reply #9 on: January 22, 2011, 13:33:38 pm » |

|

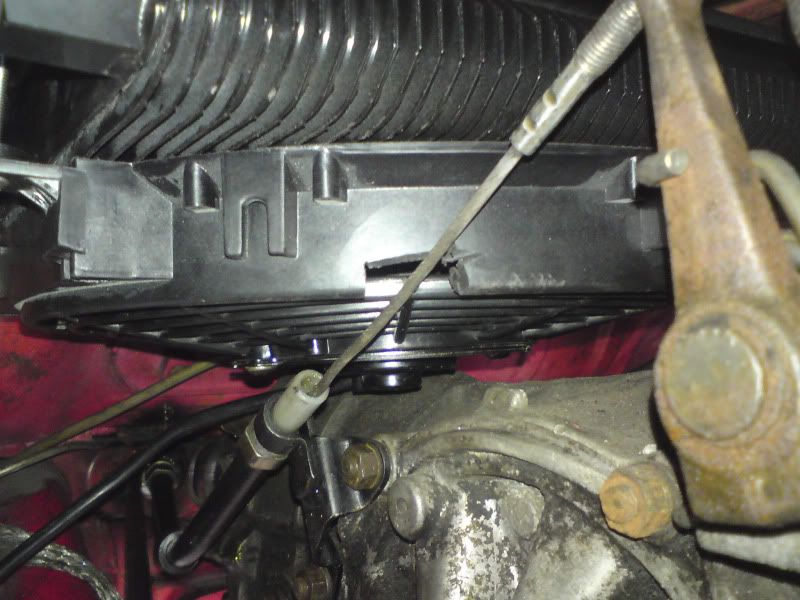

Then waiting for other parts I did a 35 work day with a buddy. he worked on his A310 Alpine and I prepared the car for the engine. Additional gauges fitted  Fuel pump and safety relais fitted   Oil thermostat is finished  and a hell of work with the cooler. It is a 96 plate with fan and a temperature switch for the fan. It sits sooo tight - you can see that I had to cut a bit for the clutch cable   also the torque bars have been fitted   after some clutch cable problems because of a badly welded tube I made a little adapter and until now it seems to work. Luckily we have a lathe in our shop   |

|

|

|

« Last Edit: January 30, 2011, 21:24:35 pm by red baron »

|

Logged

Logged

|

|

|

|

|

red baron

|

|

« Reply #10 on: January 25, 2011, 11:11:08 am » |

|

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Type1/DVK

|

|

« Reply #11 on: January 25, 2011, 13:27:36 pm » |

|

Everywhere expensive fittings but not here  especially in this part where it's visible. And is the filter in front of the pump circuit of behind? (pressure part) |

|

|

|

|

Logged

Logged

|

DDD#8 - 14.74sec @ 1776cc - Member of: DVK ~ Der Vollgas Kreuzers - www.ultimatevw.nl - and racing engines |

|

|

|

red baron

|

|

« Reply #12 on: January 25, 2011, 13:42:26 pm » |

|

it is not visible because I have a wheel there. and the filter is before the pump. I'm still a student and had a tight budget. thats why I had to save money on some parts. And while I see the advantages of fittngs in the oil system I dont see them in the fuel circuit as long as I dont want to remove the engine or parts of it regulary. My ocus was to get all the best parts for the internals of the engine and save some money on simple hoses for fuel and crankcaseventilation.

But you are totally right that it does look much better if you use it everywhere. Maybe I cann add them later.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

red baron

|

|

« Reply #13 on: January 29, 2011, 18:07:04 pm » |

|

Then came the big day of starting it for the first time. This is the first engine I have built - so I was really afraid that soemthing could go wrong. Luckily I had two well experienced friends to help me. This is Lorenz and Ole (owner of Pink Panther) checking if I forgot anything.  last adjustments  also we did mount a secondary tachometer to control the engine   and here the first start..

<a href="http://www.youtube.com/v/hH-WkfoUc1Q" target="_blank">http://www.youtube.com/v/hH-WkfoUc1Q</a> |

|

|

|

|

Logged

Logged

|

|

|

|

|

red baron

|

|

« Reply #14 on: January 29, 2011, 18:09:07 pm » |

|

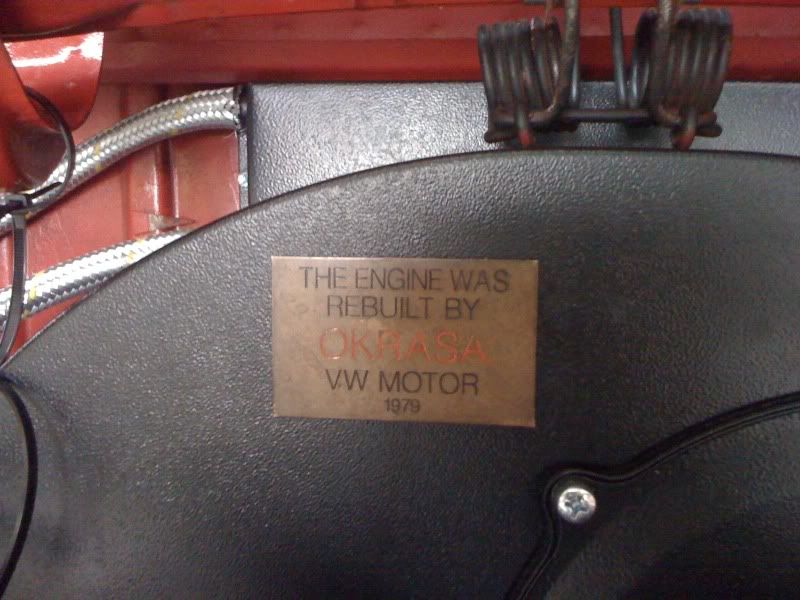

unfortunatly there were a few oil leaks so the engine came out again  but after the first run everything was fine and it really kicks!  and it now deserves his plaque  |

|

|

|

|

Logged

Logged

|

|

|

|

|

|

|

red baron

|

|

« Reply #16 on: January 29, 2011, 20:02:48 pm » |

|

Yes I used VHT engine enamel. It seems to work quite well. On the can is written that u can eighter put it in the oven or paint on parts that will heat up soon. But "chemically stable" or soemthing like that, will it be after getting hot. Thats why I decided to paint+oven because I didnt know how long it will last until the egine will run for the first time.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Nico86

|

|

« Reply #17 on: January 29, 2011, 20:59:27 pm » |

|

Ok thanks for the infos  |

|

|

|

|

Logged

Logged

|

|

|

|

|

nicolas

|

|

« Reply #18 on: January 30, 2011, 09:51:54 am » |

|

nice work. it is quite similar to the work i am doing to a 2276 engine. a lot of measurements need to be done. good to have some machining equipent at hand as well. the case i have was also not clearanced enough. maybe they only do it for chevy tab... but it is not nearly enough for a VW type rod, i have eagle 5.325 rods. not sure why you put the sender in the hole for the support bracket and not in the type3 blockoff? it seems more obvious to me just in case you want to put the engine in a bus later on  and please tell me what it is with the identification of the carbs? do you need the numbers for TUV? |

|

|

|

|

Logged

Logged

|

|

|

|

|

red baron

|

|

« Reply #19 on: January 30, 2011, 10:51:29 am » |

|

I placed the sender there because I wanted to know the oil temperature when it comes out of the sump. Yes you tipped right. The fucking TÜV. As might have seen my car has an additional H on its license plate that marks it as a classic car, saves me some taxes and insurance and I'm as well allowed to drive into the citys where normally no cars without catalytic converters are allowed. But this H also means that all changes on the car have to be period correct. Every TÜV engineer has a different point of view - so thank got that my lowered front is legalized and now the engine has to get through. to avaoid problems the case has a 1600cc marking and idf-carbs are possible to get trough TÜV - but just the small 40's. Since I bought 44, I had to restamp them. Nobody will see the difference and everything should work. Just the exhaust topic is a porb, because we need heaters and a phat boy is probably too loud and some might not consider it as period-correct. you see - lot of problems even after you first run the engine ...  |

|

|

|

|

Logged

Logged

|

|

|

|

|

nicolas

|

|

« Reply #20 on: January 30, 2011, 11:18:22 am » |

|

i just saw that you used the big plug on the case and not the hole for the bracket...  but i can understand your idea. i also understand the problems with the TUV... but here in Belgium there isn't any standard... so that makes things even worse IMHO. thanks for the info. another quick question, did you use A or B pistons with the 78.4 crank? judging by the weight i am thinking A's, but i can be wrong. |

|

|

|

|

Logged

Logged

|

|

|

|

|

red baron

|

|

« Reply #21 on: January 30, 2011, 15:28:02 pm » |

|

I'm not sure if a or b were the pistons for big stroke. but the ones I bought are the ones for big stroke. I bought them from udo - so maybe he reassembles the sets.

But obviously you belgian guys have a lot of freedom to get your car road legal. I remember a few guys driving on the autobahn with slicks to DDD... Maybe I should try to get a belgian license ^^

|

|

|

|

|

Logged

Logged

|

|

|

|

|

volkskris

|

|

« Reply #22 on: January 30, 2011, 15:38:53 pm » |

|

I'm not sure if a or b were the pistons for big stroke. but the ones I bought are the ones for big stroke. I bought them from udo - so maybe he reassembles the sets.

But obviously you belgian guys have a lot of freedom to get your car road legal. I remember a few guys driving on the autobahn with slicks to DDD... Maybe I should try to get a belgian license ^^

they're B pistons then. and keep the german license. it sucks here in belgium, at least you know yer cars are safe. |

|

|

|

|

Logged

Logged

|

|

|

|

|

red baron

|

|

« Reply #23 on: January 30, 2011, 16:41:10 pm » |

|

I'm not sure if a or b were the pistons for big stroke. but the ones I bought are the ones for big stroke. I bought them from udo - so maybe he reassembles the sets.

But obviously you belgian guys have a lot of freedom to get your car road legal. I remember a few guys driving on the autobahn with slicks to DDD... Maybe I should try to get a belgian license ^^

they're B pistons then. and keep the german license. it sucks here in belgium, at least you know yer cars are safe. You're right...at least I understand the neccesarity if you can go over 200km/h on the autobahn that most cars are safe. |

|

|

|

|

Logged

Logged

|

|

|

|

|

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge