|

BeetleBug

|

|

« Reply #30 on: January 23, 2012, 09:38:24 am » |

|

Good to have you back Fredrik and thanks for sharing your pictures and experiences. I think you have just found out why almost every NA engine, regardless of size, produces from 160 to around 180 hp. The situation got even worse when well known suppliers started to mass produce (CNC standardized) heads with poor performing ports. After spending around 20 hours of working on the heads for my 1641ccm engine this weekend I HOPE I have managed to improve the flow from the-out-of-the box 130 cfm @ 12mm lift (25") 044`s with 40x35.5 valves, original bore. It is very tight around both valves in a original bore, there was sharp edges around all the valve guides and I did a traditional port job in the intake channels + opened up the exhaust just a little and removed the exhaust guide. Porting will always be a compromise when you do not remove the valve guides and valve seats. Take a look here how Johannes managed to get 197cfm from a 40mm intake valve: http://cal-look.no/lounge/index.php/topic,3257.0.html (page 4) Note how he totally changes the shape of the intakes and how he use Belzona to fill the long radius. If you apply a thin coat of oil in your intake channels you can use fug foam (fugskum from Biltema) to make a model of your intake channel: Pics borrowed from a Norwegian build thread: [ Attachment: You are not allowed to view attachments ] [ Attachment: You are not allowed to view attachments ] I`m afraid I do not have any experience with the Street Eliminators. Please keep us updated, it is always interesting to read, and learn, what is going on in your garage. Best rgs Kalle |

|

|

|

|

Logged

Logged

|

10.41 - 100ci - 1641ccm - 400hp

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #31 on: January 23, 2012, 21:58:27 pm » |

|

Thanks Beetlebug. First i have to say that i also think this CNC this And CNC that is quite funny. There are people that really thinks that when it is made by CNC it has to be much better than hand made.. Yes i have been reading JP postings about the mouse motor for approx 100 times. I have also tried to make a look alike copy of the head and ended up with flow around 160cfm without the intake. Now after playing around with the S/F heads i have came up with the conclusion that there is no idea to try and test intake channels shapes without the intake. I think it has to do with the quite short intake channel that STD type VW heads have. And i also believe this is the reason why JP had much higher velocity at intake flange that is normally recommended on the mouse Morton.. This evening i have spent couple of hours playing around with Street eliminators. And luckily i managed to improve the flow quite a bit. Also the turbulence went much better. Problem was in the inner radius. Basic prepp guides says often that leave the inner radius alone. Its to small anyway.. And i think this is true with 90% of every normal in line 4 cylinder engine. But with type1 cylinderhead this seemes to be littlebit of the opposite. Inner radius shall not turn totally to the intake channel flange. It is Moore clever to continue this inner radius into the intake manifold. Of course thees are very preliminary findigs i have come up with and i have to make moore tests to be 100% convinced. Today I tried to make the inner radius much straighter and this helped alot both for the turbulence in the channel and total flow. Before the flow where in the range of 190cfm@28" with 15" of suction. With max suction of ~40" this dropped down to 176cfm@28" i want to comment here in between that i always give the flownumbers corrected to 28" of water. This way it is much better to compare if the flow decreases with higher suction or not. Back to test with moore straighter intake innerradius I where able to increase the max flow to 196cfm and with max suction this dropped to 194cfm. This shows also that i have managed to get rid of the heavy turbulence. But there are some turbulence left beacuse when the cylinder is flowed with 10-15" the flow is around 202cfm@28" Flownumbers from 2mm to max lift 2mm 53cfm 4mm 90cfm 6mm 125cfm 8mm 150cfm 10mm 173cfm 12mm 186cfm 14mm 193cfm 15.2mm 196cfm Here i have some pictures of the intakes. remember that i havent tried to make any finish on the intakes yet.     I have been "modelling" a virtual engine with pipemax. Theese heads are planned to be mounted on a 94x78 engine so in theroy it is possible to get out something between 200-215hp with correct header and intakes. I also made flowspeed tests and iám quite close to what pipemax recomends. But as usual i want to make some minor improvements before iám pleased.. I have also seen that 90% of stroker engines are often in the range of 160-180 horsepower. One reason ithink also is the aftermarket headers you find. i have tried to measure different headers and they alqays in the range of 880-900mm. This lenght is good up to maybe 6000rpm. If you want to get power above that you will need much shorter headers... Other is that intakes are quite small just above the cylinder head flange. This means that with nice heads you will moove the smalles area from intake channel up to the intake manifold.. Not good for High rpm engine.. |

|

|

|

|

Logged

Logged

|

|

|

|

pep

Newbie

Posts: 7

|

|

« Reply #32 on: January 24, 2012, 13:01:50 pm » |

|

it is good to have friends like that than Frederick  After that flow improvement I have to think twice should I use those street eliminator heads or should I use Superflow heads into my split racer in next summer  |

|

|

|

|

Logged

Logged

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #33 on: January 24, 2012, 13:50:20 pm » |

|

it is good to have friends like that than Frederick  After that flow improvement I have to think twice should I use those street eliminator heads or should I use Superflow heads into my split racer in next summer  First street eliminators then after Supeflows  |

|

|

|

|

Logged

Logged

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #34 on: January 30, 2012, 22:33:56 pm » |

|

Small update about the latest TC bargain. Couple of weeks ago I got two of Holset HX50 turbos and now my collection got a new member. This time the very popular Holset HX40 super. I have had some plans to use this turbo on the Virtual High RPM 1600 engine. This turbo should be good for +500hp but anything above 400whp would be enough for me  Here are the holset HX50  Holset HX40 Super  Unfortunately there has not been so much time to do anything special on the flowbench. Only intresting where one friends angleflows that where measured to 240cfm@28" before they went to his head guru. Must say that it is quite intresting to se how small size difference there are on sf heads that flows just under 200cfm to real nice superflows that flows over 230cfm. Hopefully I will have some time in the end of the week to continue with the Street flow heads. Would be nice to try find the last 5-10cfm that it missing. |

|

|

|

|

Logged

Logged

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #35 on: January 31, 2012, 23:09:16 pm » |

|

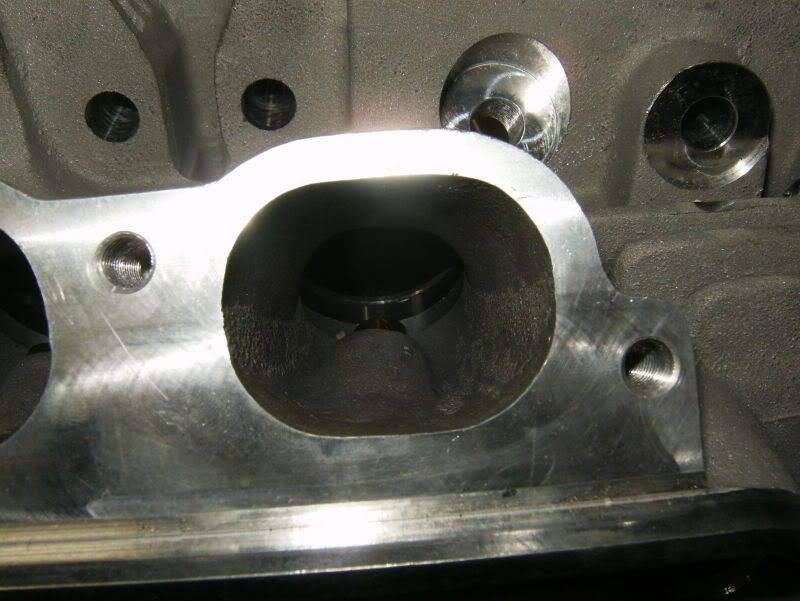

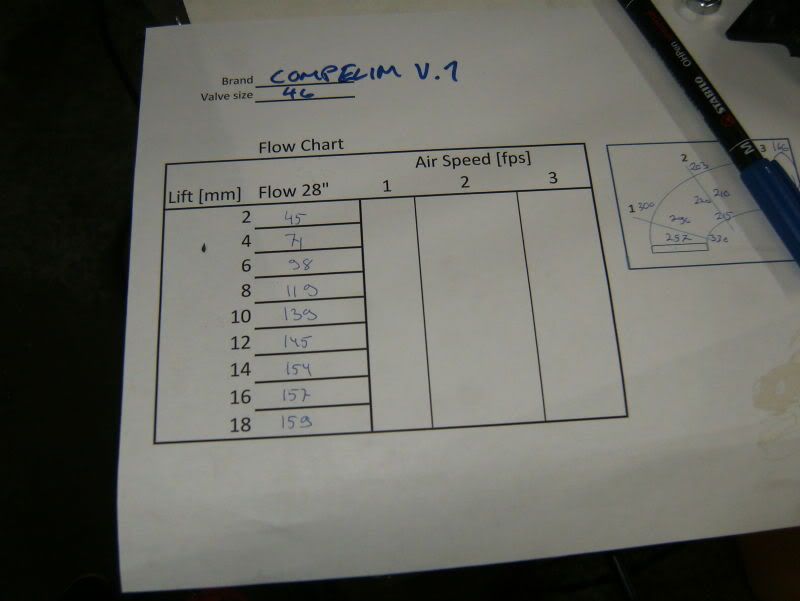

Some intresting flow results from CB unported Comp eliminators. Puide bought these heads instead of his old SF heads. Old SF flows good but target with theese are on hte "next level" what i had understud. Moore of his project you can found on his blog. http://rotta.markopuikkonen.com/Must say that the finnish of the intake/exhaust channels are poor and also the combustion chambers. But good thing is that you have good with material to start to chape them as you want. Hopefully we will be able to flow them after the port job. Combustion chamber. as you can se from hte picture there are a quite big step between seat rings and the intake channel  Intake channel  And the flow results without intake. Theese results are maybe littlebit poor by me. same and better flownumbers are atcived with much smaller valves and cheapier heads. Of course this is just a startingpoint and without a flowbench it is easy to improve the flow with 20-30cfm just by smootehing the sharp edges.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #37 on: February 16, 2012, 22:40:53 pm » |

|

Some update. Today i had a intresting evening together with pep visualizing new shorty intakes to his 2150cc. Target is to dimension the engine to give max rpm at 7200rpm so the intakes require lot of reworking. Also the header will be Taylor made by calculations made in Pipemax.   So it will be interesting to se how this engine will perform during this years dyno shoot i that we will have the weekend before Finnish VW open. If everything clicks toghether i think it will be very close to 100hp/l.. But lets se |

|

|

|

|

Logged

Logged

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #38 on: May 23, 2012, 20:41:07 pm » |

|

After reading the header topic i thought that maybe i should update littlebit about the PEP 94x78 engine that i was helping with during the winter. As you can read from earlier posts we where grinding the heads to find moore flow. Trouble was that what ever we did the cylinder head did not flow any moore than 170cfm@28" After mounting a short intake the cylinder head waked alive. With small modification we where able to rise the flow up to 200cfm@28". After this the intake manifolds where shortened and ported we manage to get the flow to 195cfm@28". Good thing was that when the heads where flowed with max depression of 35-40" the flow did not descend at al. Because non of us two has long experience in atmo engine building we started to put in values to the pipemax program. Must say that without A.Norrback help i would never found out good tricks and hints about the pipemax program. First thing was to put in engine values into the program. When cylinder head flow where measured it was possible to se which rpm these heads would give a VE of 110%. Results was that 7200rpm would be a good target to try optimize intake and exhaust lenghts to. with these numbers pipemax gave a potential of 200-220hp. Camshaft where decided to be changed from FK87 to Fk48. Both camshafts are quite equal but what i have understud the FK40 series has a improved Valvetrain dynamics. For 7200rpm operation milder camshaft would have worked fine but plan was to put a camshaft that could work later on with wilder cylinder heads. With this camshaft we calculated that a static compressions ratio should be in the range of high 12 to 13;1. Camshaft where dialed straight up because it could be a good starting point. To shorten the intakes Pep made a hell of a job. First they where shortened then splitted and then welded alot. But pep did manage to get the length down to appr 15cm.. Exhaust where then modified from Al´s header that he bought from www.aircooled.fi. Primary pipe length where cut down to 720-750mm and collector hole where cut up to ~50mm. Target for pep was to attend on out every year dyno competition that we have here in Vasa. This year we changed the rules to compete in HP/litre and target was to get over the magical 100hp/l. As usual with competitions like this they come 1 week to early, night hours where used to get the engine started. Junk VW body was used as a test bench just to be able to test the engine on the rolling dyno. So the car where driven its first meter right on to the dyno so fine tuning where left to be done at the dyno. First pulls where done and AFR showed littlebit on the lean side but because lack of bigger jets we decided to make a pull. first pull gave something like 160whp and with Ignition tuning the horsepower went up to 176whp @7100rpm. But we did not continue because the AFR where on the lean side. Positive thing is that last year best pull where in the range of 155whp. Also there where not shorter velocity stacks available so the intakes are something like 15-20mm to long. So i believe that there are some hp to be found with Intake tuning and to get the AFR right. Some build up photos    Cave ManPorting his intakes  intakes spot welded together before fill up  Engine mounted to the car 3 in the morning. Only 9h left to the dyno  Pep did also win this year competition. I have been using the 15% trans loss calculation and this gave 93hp/l which is ok number for home made engine with homemade intakes, heads and exhaust. this proves by me that if you use decent parts together and some calculations it is possible to build a nice "powerful" engine without expensive parts. Unfortunately i don't have a dyno chart available because we run out of color in the printer. Videos and pics from the happening can be found at http://rotta.markopuikkonen.com/?cat=39http://avipics.nettigalleria.fi/main.php?g2_itemId=3010http://terpanturinat.blogspot.com/http://pepgarage.blogspot.com/http://www.volkkaripalsta.com/keskustelu/viewtopic.php?f=7&t=39599&start=150 |

|

|

|

« Last Edit: May 23, 2012, 20:55:36 pm by Fredrik Grönlund »

|

Logged

Logged

|

|

|

|

|

BeetleBug

|

|

« Reply #39 on: May 23, 2012, 21:27:35 pm » |

|

Thanks for sharing this interesting info and congrats with the results. I'm a bit surprised that you went for a 40 series cam as I thought it was common knowledge that they are engine breakers. Yes, they produce power but anything above the FK46 will eat lifter bores for breakfast and I have yet to see a mag case survive a season with FK47 and above.

|

|

|

|

|

Logged

Logged

|

10.41 - 100ci - 1641ccm - 400hp

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #40 on: May 24, 2012, 08:05:44 am » |

|

Thanks for sharing this interesting info and congrats with the results. I'm a bit surprised that you went for a 40 series cam as I thought it was common knowledge that they are engine breakers. Yes, they produce power but anything above the FK46 will eat lifter bores for breakfast and I have yet to see a mag case survive a season with FK47 and above.

Ok that was new information for me about the FK40 series. I had understud that it is the FK80 series that is moore harmfull with not as good Valve train dynamics as the FK40 series.. But there are always days when you learn something NEW. What other good camshaft are availble. Yes JPM but how is it with other manufactures? |

|

|

|

|

Logged

Logged

|

|

|

|

Erlend / bug66

Global Moderator

Hero Member

Posts: 958

SCC Event

|

|

« Reply #41 on: May 24, 2012, 08:14:40 am » |

|

Thanks for sharing this interesting info and congrats with the results. I'm a bit surprised that you went for a 40 series cam as I thought it was common knowledge that they are engine breakers. Yes, they produce power but anything above the FK46 will eat lifter bores for breakfast and I have yet to see a mag case survive a season with FK47 and above.

Ok that was new information for me about the FK40 series. I had understud that it is the FK80 series that is moore harmfull with not as good Valve train dynamics as the FK40 series.. But there are always days when you learn something NEW. What other good camshaft are availble. Yes JPM but how is it with other manufactures? Web 86C? 272degrees at 0,05" lift, 0,585" valvelift with 1,4 rockers. |

|

|

|

|

Logged

Logged

|

The '67:

10.626 @ 132mph, SCC 2016

10.407 @ 134mph, SCC 2017

10.221 @ 135mph, SCC 2018

The '59:

Not yet..

|

|

|

SuperTrigger

Newbie

Posts: 41

|

|

« Reply #42 on: May 25, 2012, 09:37:18 am » |

|

Thanks for sharing this interesting info and congrats with the results. I'm a bit surprised that you went for a 40 series cam as I thought it was common knowledge that they are engine breakers. Yes, they produce power but anything above the FK46 will eat lifter bores for breakfast and I have yet to see a mag case survive a season with FK47 and above.

Ok that was new information for me about the FK40 series. I had understud that it is the FK80 series that is moore harmfull with not as good Valve train dynamics as the FK40 series.. But there are always days when you learn something NEW. What other good camshaft are availble. Yes JPM but how is it with other manufactures? I had to ask about this from friend of mine that has used FK47 and FK 48 cams from 2010. And he said that he hasn't noticed anythin that relates to wear of lifterbores. But he is using aluminium case, so I have to ask is this iproblem noticed only with magcases? -Puide- |

|

|

|

|

Logged

Logged

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #43 on: January 23, 2013, 21:00:00 pm » |

|

Hello it has been a while since last topic update. To prove that there is life and things happening outside the "facebook" and blogg world i thougt that its time to update whats happening in my garage. I must admit that it easier to just read what other do than start to update own topic. Of course last year has been quite silent because of house buying etc. And good thing with a hobby is that if there is no inspiration just have a break. That's the difference compared to normal day work.. But couple of weeks ago i started to work on my friends oval again. Plan was to remove the engine and change transmission to SF dogleg trans. Because the trans has to be equipped with standard nosecone i decided to rise the trans with couple of cm (2.5inces for us readers  ) Because i had started the grinder saw i decided to tube and narrow the rear axle also at the same time. Rear axles are these almost unbreakable Karpiola axles which are 3" narrower than standard narrow axles. To get more free space to inner fender i decided to use long axle tubes and narrow these to fit. This mean springplates are narrowed with ~106mm when drums are moved with just 76.2mm. target with the car is to build a nice sunday cruiser or as the car owner say decent car to bring milk from 7-eleven. This mean it needs a rear seat and otherwise standard interior. lets See how it turns out.. Some pictures Work started. I hate to saw i rusty cars so this project is perfect. No brown dust coming during dismantling    i decided to rise the rear tube so it would apear to be orginal. Maybe not the optimal way but it is inportant that car inspection will not se imediately that there has been lot of changes made..   Next was to narrow the axle tubes. easiest way for me was to reve the cup and move it inwards with 106mm. Theese tubes are one year only 1967 because they where laying around. Thanks to pep for theese.  Cups welded  Now when tubes where ready the spring tube where next. This where made with suport sleeves to keep them as straight they where.    Spring tube welded  After this i started to muck up everything to test the right height. Best compromise seemed to be Trans 6.5cm higher than standard. With this it should be possible to close the enginelid without alternator pulley hitting it.    Next thing will be to start welding it back toghether. If your are interested to se other cars that this carowner owns visit his blogg http://maazasvw.wordpress.com/ |

|

|

|

|

Logged

Logged

|

|

|

|

Niklas L

Newbie

Posts: 8

|

|

« Reply #44 on: January 25, 2013, 09:09:22 am » |

|

I know you won´t find rust on that one.  Don´t forget - virtualdragracing at my cottage in four weeks! |

|

|

|

|

Logged

Logged

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #45 on: January 25, 2013, 22:43:47 pm » |

|

I know you won´t find rust on that one.  Don´t forget - virtualdragracing at my cottage in four weeks! virtualdragracing event added and reserved in my calender  |

|

|

|

|

Logged

Logged

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #46 on: January 25, 2013, 22:54:40 pm » |

|

Would someone have good suggestions for good cylinderhead instead of the CB 044.

Oval turbo engine had a pair of 044 but there has been lot of different issues with them. So now I'm searching for some other alternatives. Of course JPM heads would e perfect but littlebit out of scope for this engine.

Most important would be good material, standard look cooling fins and additional material around intake channels.

Valve size maybe 42 or 44 on intake and max 37 on exhaust but there has to be material between the valve seats.

Also they should be equipped with good quality valves etc already from box..

|

|

|

|

|

Logged

Logged

|

|

|

|

|

BeetleBug

|

|

« Reply #47 on: January 26, 2013, 08:40:38 am » |

|

.

Oval turbo engine had a pair of 044 but there has been lot of different issues with them.

Would you mind telling us what kind of different issues? It looks like Street Eliminator is a popular choice among racers over there. Might be worth checking out? Best rgs BB |

|

|

|

|

Logged

Logged

|

10.41 - 100ci - 1641ccm - 400hp

|

|

|

wph

Jr. Member

Posts: 94

|

|

« Reply #48 on: January 26, 2013, 18:08:19 pm » |

|

Would someone have good suggestions for good cylinderhead instead of the CB 044.

Oval turbo engine had a pair of 044 but there has been lot of different issues with them. So now I'm searching for some other alternatives. Of course JPM heads would e perfect but littlebit out of scope for this engine.

Most important would be good material, standard look cooling fins and additional material around intake channels.

Valve size maybe 42 or 44 on intake and max 37 on exhaust but there has to be material between the valve seats.

Also they should be equipped with good quality valves etc already from box..

Bugpack StreetPro regarding casting quality and material but they lack the extra material around intake flanges and only 40x35.5 valves. Very hard and dense material, permanent mould cast, no core shifting. |

|

|

|

|

Logged

Logged

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #49 on: January 26, 2013, 20:40:50 pm » |

|

.

Oval turbo engine had a pair of 044 but there has been lot of different issues with them.

Would you mind telling us what kind of different issues? It looks like Street Eliminator is a popular choice among racers over there. Might be worth checking out? Best rgs BB There has been al kind of small things like, cracked valve keepers, cracked retainers, brittle material and now cracked valveguides also head material is somewhat brittle but then also soft. I can understand that problems with the valvetrain could be tracked back to bad valve train dynamics. But i know very little about the earlier use of thees heads. They where mounted on a atmo stroker and driven occasionally on street and strip. What camshaft etc i don't know. Before they where used on this turbo engine they where opened and valve seat refreshed. It was then when cracked valve locks and retainers where found. Also intake valves had been leaking slightly on the surface against exhaust valves... After this slight refreshment car has been dynoed and driven on the strip for 5-6 times (starts). Cooling belt has always been used because otherwise it would not be a streetcar  Now when engine where opened i found a cracked exhaust valve guide inside the exhaust side of the turbo. When i started to look inside the exhaust port i found out that 2 exhaust guides had no part left into the exhaust port third where almost loose and the fourth where intact. I have no pictures yet but when i get back my valve tool i will open them up and take pictures. As conclusion: Cracked valve locks/retainers is propably because of bad valve train dynamics. Leaking valve seats because of the bad design where exhaust valveseat is touching intake valve seat. This will cause the intake seat to be warmed very unequally... This exhaust guide damage is then quite strange. No marks from that valves has been hitting the pistons, valve geometry is OK and i suppose that valve dynamics also because of good bran camshaft. Problem is also that i don't know what they have went through earlier life as atmo heads. Could it be that they have been running without good cooling and they have "over cooked" the heads. Why I'm after for some other head is that i would prefer to have valve bosses left on the exhaust side, better material and also valve seats mounted so that there is material left between them. Then also cooling fins as standard heads... 4 |

|

|

|

|

Logged

Logged

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #50 on: January 26, 2013, 20:47:49 pm » |

|

Would someone have good suggestions for good cylinderhead instead of the CB 044.

Oval turbo engine had a pair of 044 but there has been lot of different issues with them. So now I'm searching for some other alternatives. Of course JPM heads would e perfect but littlebit out of scope for this engine.

Most important would be good material, standard look cooling fins and additional material around intake channels.

Valve size maybe 42 or 44 on intake and max 37 on exhaust but there has to be material between the valve seats.

Also they should be equipped with good quality valves etc already from box..

Bugpack StreetPro regarding casting quality and material but they lack the extra material around intake flanges and only 40x35.5 valves. Very hard and dense material, permanent mould cast, no core shifting. How is the material with DDS or mofoco heads. Theese have additional material around intake ports so some porting could be done. Most important would be to find heads that have good core for port work and then the material as good as possible to withstand the abuse.. |

|

|

|

|

Logged

Logged

|

|

|

|

wph

Jr. Member

Posts: 94

|

|

« Reply #51 on: January 26, 2013, 22:15:26 pm » |

|

This exhaust guide damage is then quite strange. No marks from that valves has been hitting the pistons, valve geometry is OK and i suppose that valve dynamics also because of good bran camshaft.

Actually this is not uncommon, across the big pond it seems to be a practice to get rid of the part of exhaust guide protruding into the port because of the cracking. Too big risk of a turbine damage. There's way around it, use a steel guide with a bronze K-line sleeve and you're good to go. Good enough for Top Fuel engines... |

|

|

|

|

Logged

Logged

|

|

|

|

|

modnrod

|

|

« Reply #52 on: January 27, 2013, 05:03:22 am » |

|

How is the material with DDS or mofoco heads. Theese have additional material around intake ports so some porting could be done.

Most important would be to find heads that have good core for port work and then the material as good as possible to withstand the abuse..

I was going to suggest Mofoco heads. Leaving aside all the personality on some forums about them, their as-cast density is very good. Side-by-side with VW 355 heads, they look and feel denser and heavier. They would be my first option easily if I ever needed new DP heads, but I normally play with little baby motors under 1700cc, not sure how big you need to go on ports or valves. |

|

|

|

|

Logged

Logged

|

|

|

|

|

BeetleBug

|

|

« Reply #53 on: January 27, 2013, 08:48:59 am » |

|

Actually this is not uncommon, across the big pond it seems to be a practice to get rid of the part of exhaust guide protruding into the port

because of the cracking. Too big risk of a turbine damage.

I grinded down the part of the exhaust guide that is seen in the channel on my little 1641 engine but then again only using a 35mm valve. After 1 season of racing and street driving + the dyno and map session I have 2-3% leak (cold engine). Very interesting to read about heads and material and I'm surprised to learn about your problems with the 044's. Look at Niklas and his 1641ccm with 044's pushing 400hp at 3 bar (40 psi) and 9.55 and 142mph. If I'm not mistaken he is on his third season with the same heads. Keep us updated Fredrik. I find your thread really inspirational and some Finish sisu is just what we need to keep us warm. Best rgs BB |

|

|

|

|

Logged

Logged

|

10.41 - 100ci - 1641ccm - 400hp

|

|

|

|

Ragtop

|

|

« Reply #54 on: January 27, 2013, 18:33:40 pm » |

|

Niklas heads did not really like 3 bars. The left one cracked and the right one is a bit torched. But that might be due to the pinnbolts not being strong enough and the heads lifted

|

|

|

|

|

Logged

Logged

|

Turbo Town "Home of the overboost addicts"

|

|

|

|

BeetleBug

|

|

« Reply #55 on: January 27, 2013, 18:42:01 pm » |

|

Niklas heads did not really like 3 bars. The left one cracked and the right one is a bit torched. But that might be due to the pinnbolts not being strong enough and the heads lifted

Thanks for sharing Johan. So now we know that we should probably not go above 3 bar  . Good thing that the 044`s are easily available and very cheap. |

|

|

|

|

Logged

Logged

|

10.41 - 100ci - 1641ccm - 400hp

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #56 on: January 27, 2013, 20:44:26 pm » |

|

I have thought also that theese 044 heads are of quite good quality and propably they are. Problem is that theese where used and i don´t know how they have been used or abused.

It is just the experience until now that makes me wonder of other alternatives.

About exhaust ports i have never understud the reason why they remove the valve guide boss. It is there to give additional support for the valveguide and also protect the valve guide from warm exhaustes.

Also from flow point of view it is better to have a flow shaped boss instead of round bar..

|

|

|

|

|

Logged

Logged

|

|

|

|

|

leec

|

|

« Reply #57 on: January 27, 2013, 22:10:06 pm » |

|

Can I ask for a bit more detail on how you narrowed your axle tubes. It looks like you did them at the gearbox end?

Lee

|

|

|

|

|

Logged

Logged

|

|

|

|

|

bedjo78

|

|

« Reply #58 on: January 27, 2013, 22:45:51 pm » |

|

is it standard length torison bar on narrowed torsion housing??

|

|

|

|

|

Logged

Logged

|

|

|

|

Fredrik Grönlund

Newbie

Posts: 39

|

|

« Reply #59 on: January 27, 2013, 22:57:38 pm » |

|

Can I ask for a bit more detail on how you narrowed your axle tubes. It looks like you did them at the gearbox end?

Lee

Procedure was quite easy. Important first is to measure the length what it is before. Then i cutted and grinded of the weld that holds the Hemispherical plate on the axle tube. After this i cutted the tube to desired length and re-attached the hemispherical plate. It is important to attach this straight otherwise it will not move as it should. I made this in a turner with help of a indication clock. Then i tigwelded it back together. What is important is to measure two lenghts. First the length from plate edge to some zeropoint (i used the bearing surface) other one is axle tube length from the bottom of the plate. With these it is then easy to to shorten the tube to the right length and to get the plate in right position. |

|

|

|

|

Logged

Logged

|

|

|

|

|

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge