|

Andy Sykes

|

|

« Reply #720 on: April 04, 2014, 17:35:14 pm » |

|

|

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

Erlend / bug66

Global Moderator

Hero Member

Posts: 958

SCC Event

|

|

« Reply #721 on: April 04, 2014, 19:20:55 pm » |

|

It looks like the exhaust is fairly close to the coils on 3/4 side?

|

|

|

|

|

Logged

Logged

|

The '67:

10.626 @ 132mph, SCC 2016

10.407 @ 134mph, SCC 2017

10.221 @ 135mph, SCC 2018

The '59:

Not yet..

|

|

|

|

Andy Sykes

|

|

« Reply #722 on: April 05, 2014, 14:58:51 pm » |

|

It's close but not that close  |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #723 on: April 07, 2014, 19:46:43 pm » |

|

|

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #724 on: April 08, 2014, 17:54:30 pm » |

|

|

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

spoolin70

|

|

« Reply #725 on: April 09, 2014, 07:17:21 am » |

|

Hi Andy Great progress, do you actually sleep  Are you going with the air box idea for the turbo's intake ? I was wondering if it was possible for two turbos that suddenly take a big gulp of air when spooling up to effectively empty the air box or would this just create a vacuum to pull more air in ? Thanks Darren |

|

|

|

|

Logged

Logged

|

|

|

|

|

Andy Sykes

|

|

« Reply #726 on: April 09, 2014, 19:54:20 pm » |

|

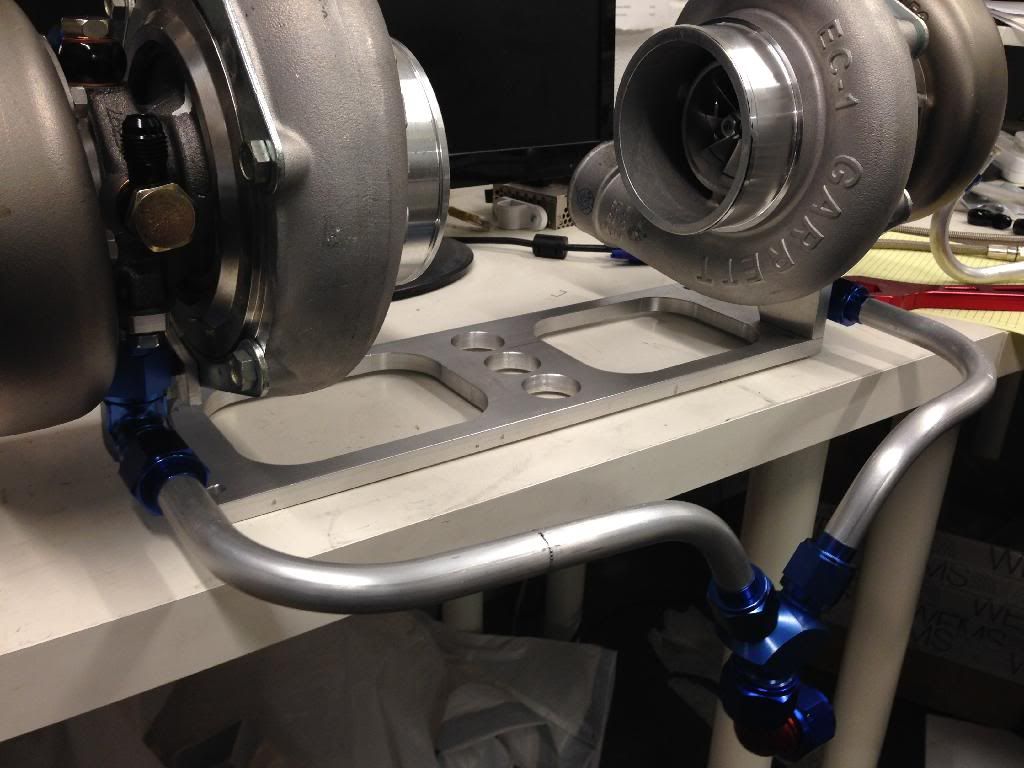

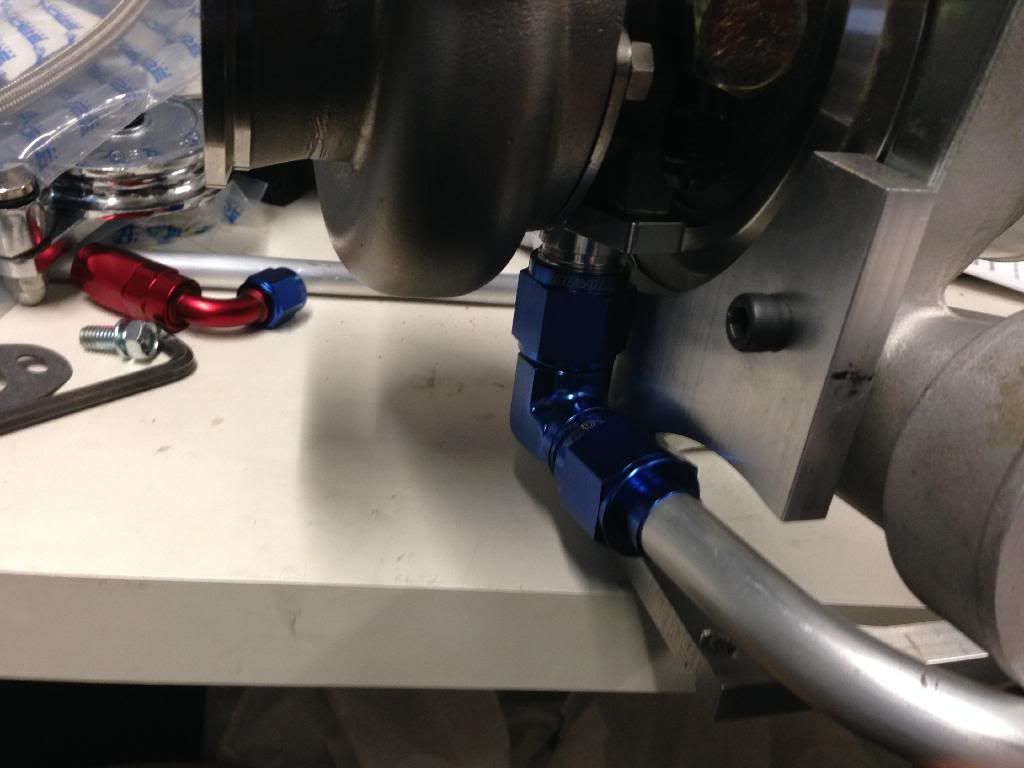

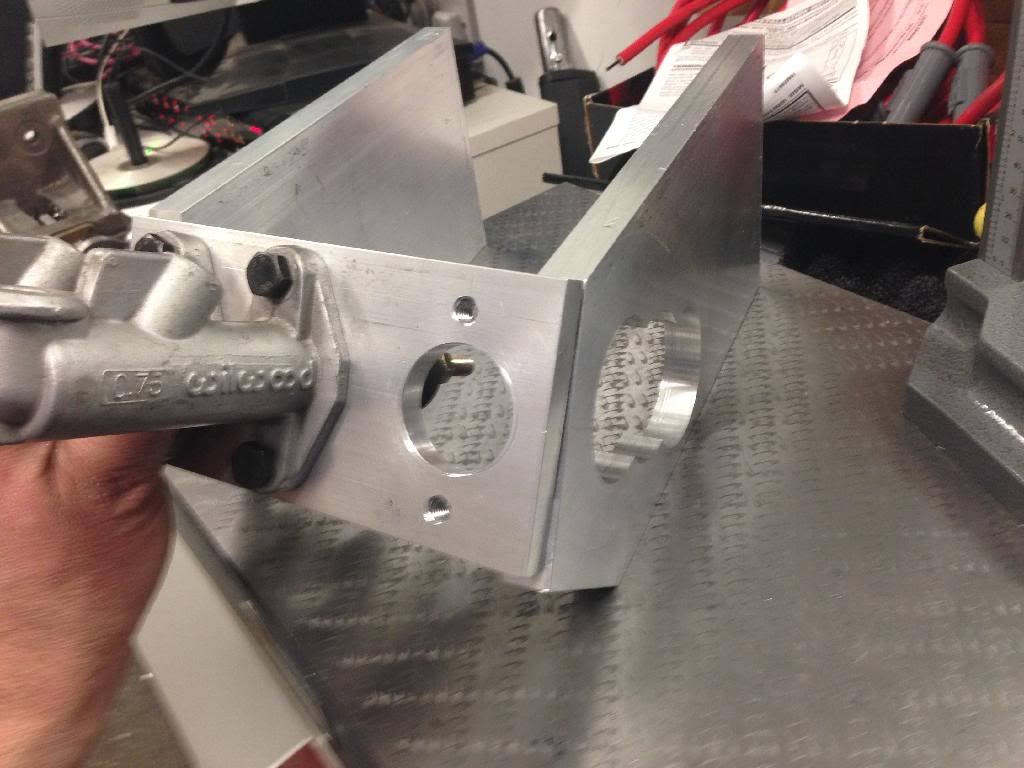

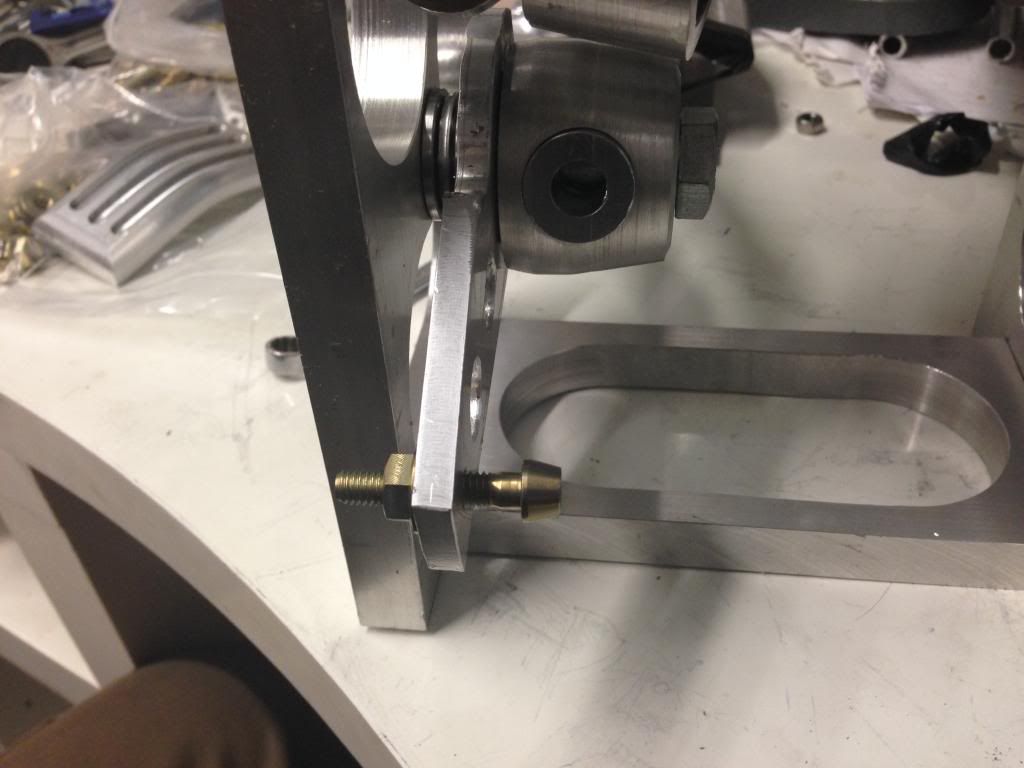

Cheers thanks, it's not to every bodies taste, but what is ? lol I'm enjoying myself . I have some cast 4" bends on the way that I can make fit so I've scrapped the air box idea Bit more on the hard lines for the oil  And finally got round to bolting the front flip,mount together to fit to the car so we can make the flip front fit nice   Cheers Andy |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Taylor

|

|

« Reply #727 on: April 10, 2014, 02:13:44 am » |

|

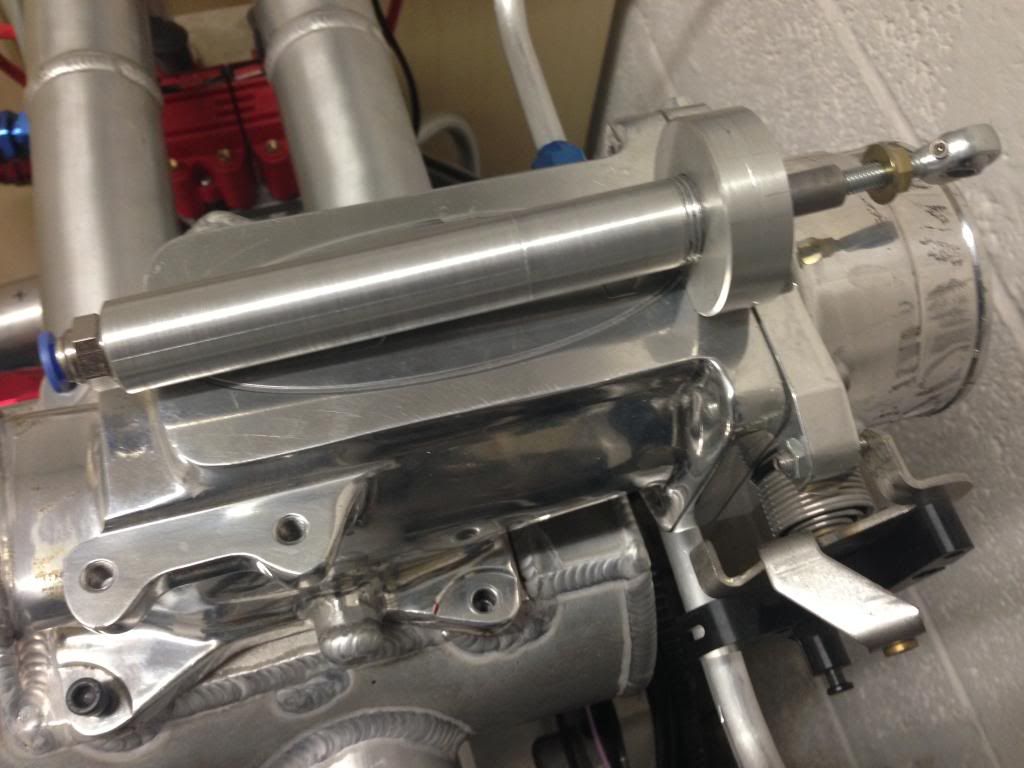

Does the picture show you pulling vacuum from the 3/4 valve cover?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Andy Sykes

|

|

« Reply #728 on: April 10, 2014, 07:37:22 am » |

|

Yes it does, but i think it's the wrong side I need to swap the covers over and fit another fitting for the turbo drain

Cheers Andy

|

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Martin

|

|

« Reply #729 on: April 10, 2014, 09:05:49 am » |

|

you should be pulling Vac from the crank Case, the idea is put neg pressure behind the rings. but you'll have to shield it so it doesn't suck up the oil thrown off the crank.

|

|

|

|

|

Logged

Logged

|

Martin 9 sec street car, its just simply not fast enough Swing axle to CV convertion is on the website now www.taylormachine.co.ukOFF/500 |

|

|

|

Andy Sykes

|

|

« Reply #730 on: April 10, 2014, 18:18:54 pm » |

|

Hi Martin

I was thinking best place was right hand rocker cover as that were the least amount of oil spray should be, and pulling a vacuum in the case will still happen from there as it would direct into the top of the case or am I

Missing something

Cheers Andy

|

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

peach_

|

|

« Reply #731 on: April 11, 2014, 00:59:13 am » |

|

Hi Martin

I was thinking best place was right hand rocker cover as that were the least amount of oil spray should be, and pulling a vacuum in the case will still happen from there as it would direct into the top of the case or am I

Missing something

Cheers Andy

By doing that arnt you creating a less effective way of vacuuming? surely if you want to create a vacuum should you do it on both sides to create equal pressure on both sets of pistons? or just create it from the middle as martin suggested? |

|

|

|

|

Logged

Logged

|

1966 java green looker- 2276 Street Machine, with standard gear box@ 14.5 (2013), With Pro Street Box @ 13.5 (2014), still more to come! SAS RENN-WAGENS and proud  #CALLOOKDRAGS |

|

|

|

Martin

|

|

« Reply #732 on: April 11, 2014, 09:18:36 am » |

|

your trying to place the area under the pistons in negative pressure, as that's where all the pumping in occurring. Rather than try and drag the air up the push rod tubes, and around the head of the lifters. if you look down the pushrod tubes you'll see there isn't a lot of room.

I like the idea of a vac pump and would like to try one out at some point, but if your rings are sealing 95%+ then just a -12 breather on the case/heads back to the drysump tank works just fine. I have placed a map sensor on the crank case this year to monitor the pressure to give a good indication of ring sealing at the higher boost levels. trying to get an indication of how the cylinders are holding up to cylinder pressures were subjecting them too.

|

|

|

|

|

Logged

Logged

|

Martin 9 sec street car, its just simply not fast enough Swing axle to CV convertion is on the website now www.taylormachine.co.ukOFF/500 |

|

|

|

Andy Sykes

|

|

« Reply #733 on: April 11, 2014, 19:46:23 pm » |

|

I get what you are saying, but im trying to pull a neg pressure in a box down a 3/4 " hose so my thinking is the best place is the place that has least amount oil flying about.

I also get the push rod tube thing but I would guess the space on 4 push rods has more surface area than 3/4" tube. I can't see putting the fitting in the centre of the block is going to make any advantage, As the presure has to be equal in the case to pull a neg pressure . I have a limited understanding of vacuum pumps and vacuum from my days working on vacuum packing machines so the above makes sense to me lol

Not saying your wrong just want the understanding

Cheers Andy

|

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

johandryselius

|

|

« Reply #734 on: April 12, 2014, 01:09:14 am » |

|

Andy! Love the hinges!!  Johan |

|

|

|

|

Logged

Logged

|

1600cc Challenge Porsche 356:

9,4386@242,48km/h; 6,1229@193,15 km/h 1,50 60 foot @ Kjula Dragway 2022

1600cc Challenge Buggy:

9,5112@225,42 km/h; 6,0624@185,85 km/h 1,38 60 foot @ Kjula Dragway 2020

Europes quickest ProStock VW:

9,8538@218,80 km/h; 6,2569@176,24 km/h 1,35 60 foot @ BRC Tierp Arena 2014

|

|

|

|

Berger

|

|

« Reply #735 on: April 12, 2014, 14:19:05 pm » |

|

If you put vacuum on the valve cover, you will make it very hard for the oil coming from the rockers to return to the cranck case. I would never do that. I think venting the valv covers at all is a bad idea. Keep up the good work  |

|

|

|

|

Logged

Logged

|

This is my simple religion: -Be cool -Don't be an asshole |

|

|

|

Andy Sykes

|

|

« Reply #736 on: April 12, 2014, 18:15:45 pm » |

|

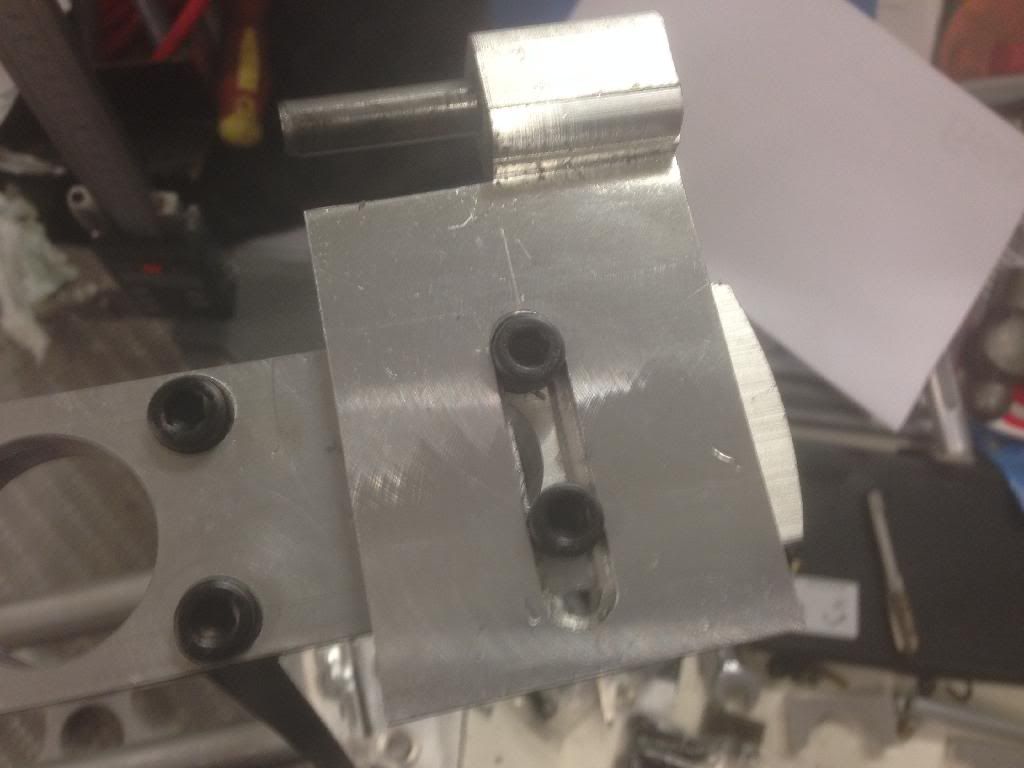

Thanks guys I guess I can tap the top of the pauter case to fit an -an16 fitting I'm mostly worried about sucking oil up ? just about finished it today      I've use 316 stainless for the hinge pin and sleeved the female part with 316 too to stop any wear on the hinge I will also do this on the door hinges Cheers Andy |

|

|

|

« Last Edit: April 12, 2014, 18:32:35 pm by Andy Sykes »

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #737 on: April 14, 2014, 19:43:15 pm » |

|

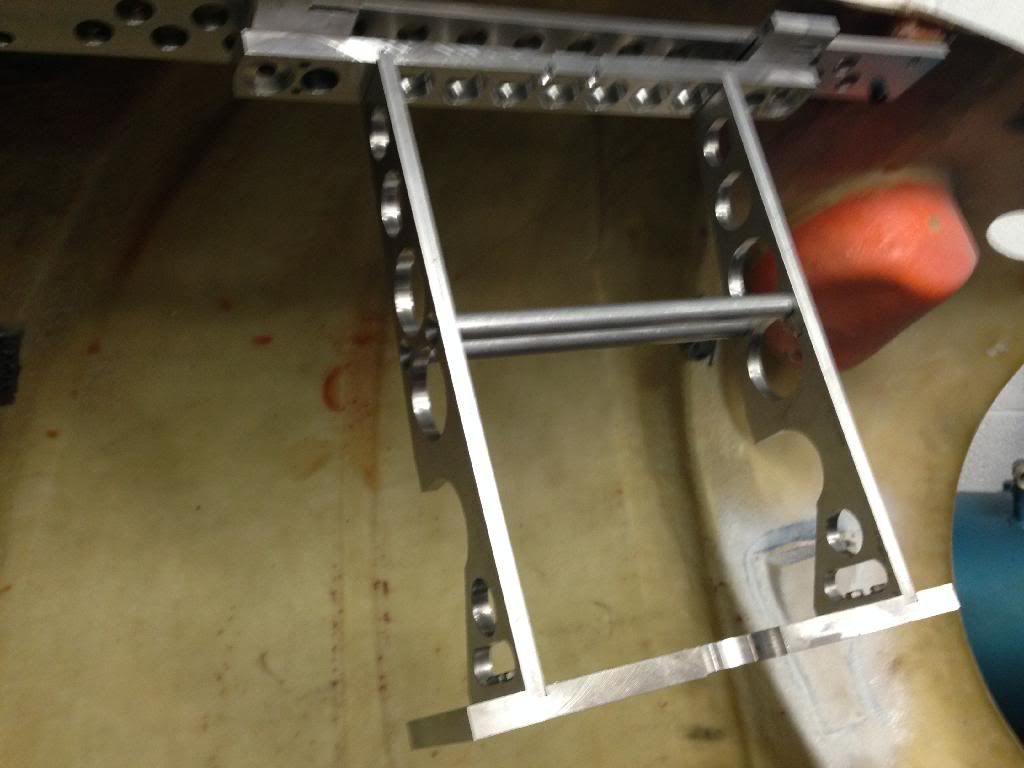

MKII door hinges from 30mm billet taken 5 hours so far   They may get lighter yet   And transmission parts arrived today £720 don't go far  Send these off the Germany tmw  Cheers Andy |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #738 on: April 15, 2014, 19:13:01 pm » |

|

|

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #739 on: April 16, 2014, 19:58:40 pm » |

|

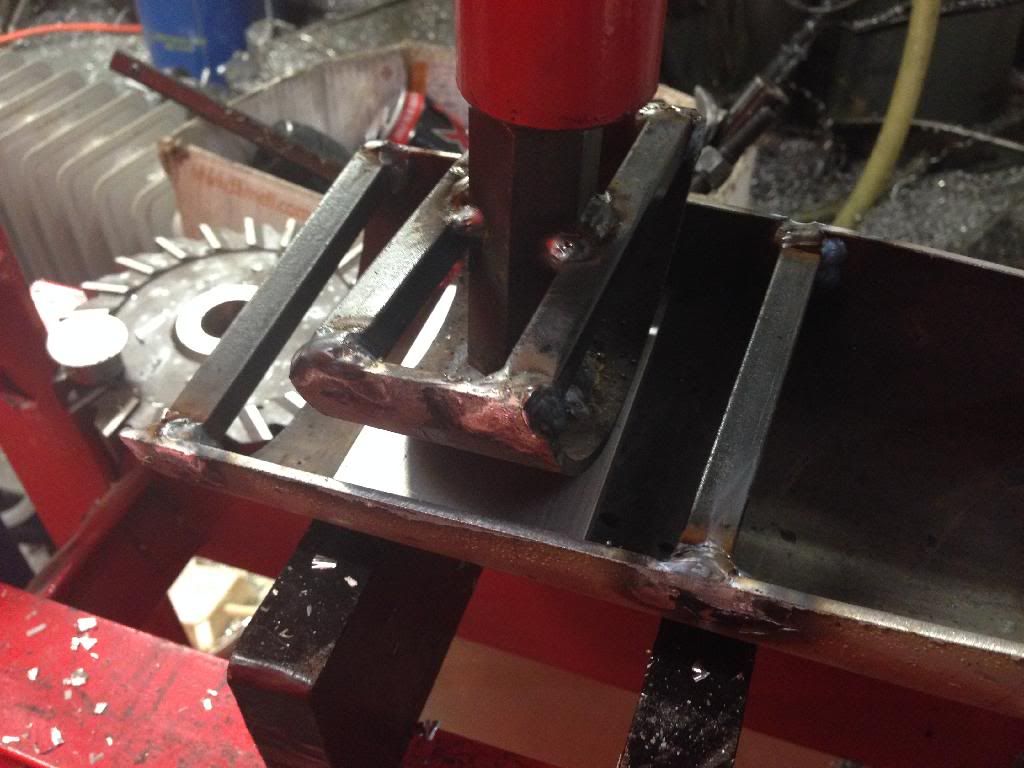

Started on the hardline for the turbos been waiting a while for the an6 to come todo the oil and water ( yes I said water lol )   And started on the pedal box this will take some time  Cheers Andy |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #740 on: April 17, 2014, 17:08:53 pm » |

|

bit more AN6 hardline arrived so I've finished the feeds and returns   bit more on the pedal box    that's it im off home cheers andy |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #741 on: April 23, 2014, 19:46:42 pm » |

|

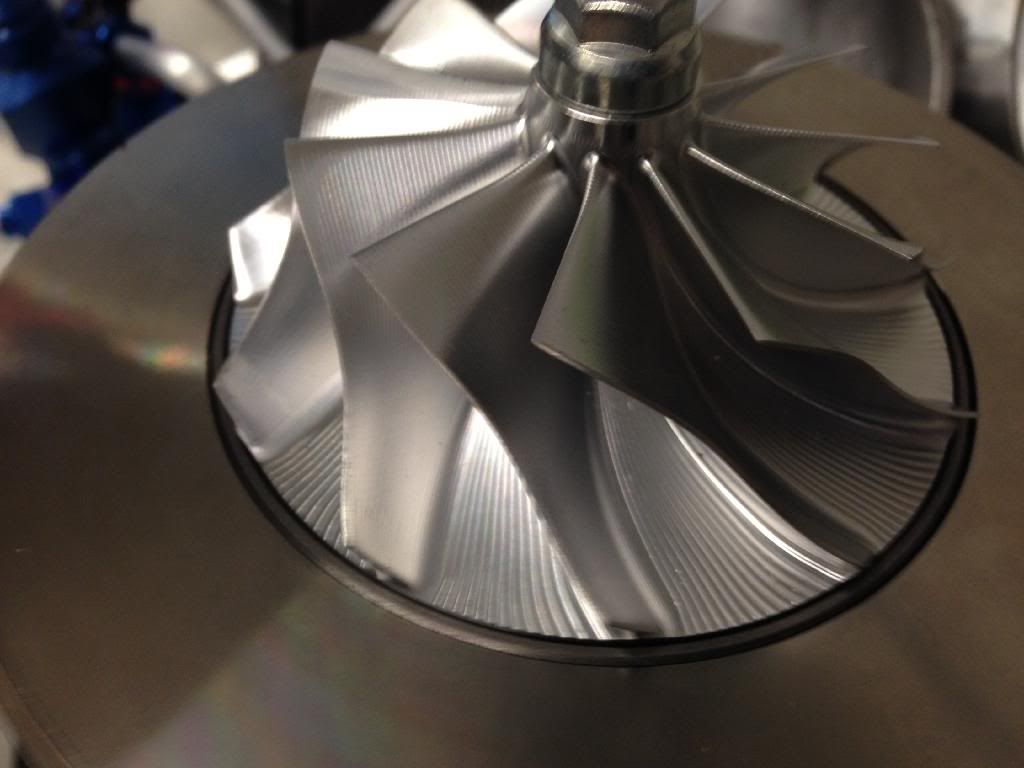

Little bit more done had to machine the compressor housing today Billet compressor wheel   Trial fit with boost tape   Did a bit more on the pedal box stop and go bits machined them and needed to bend them a bit so made a former from an old Russian diving cylinder I've had for years    Turned out good I think  Cheers Andy |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #742 on: April 25, 2014, 20:42:49 pm » |

|

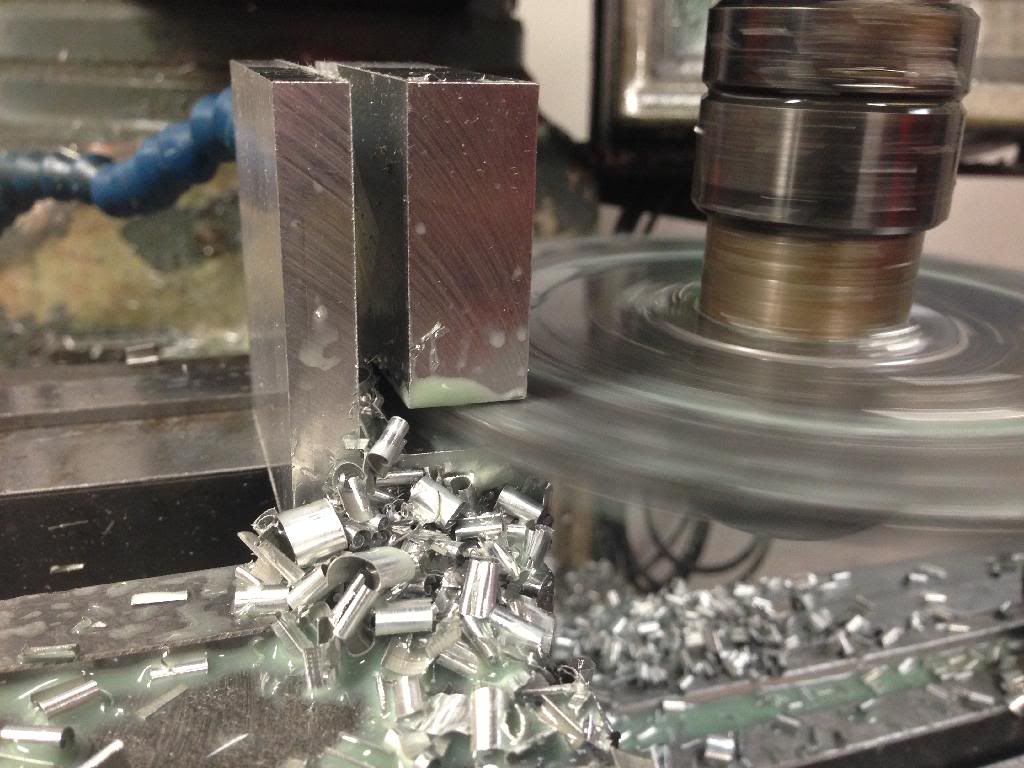

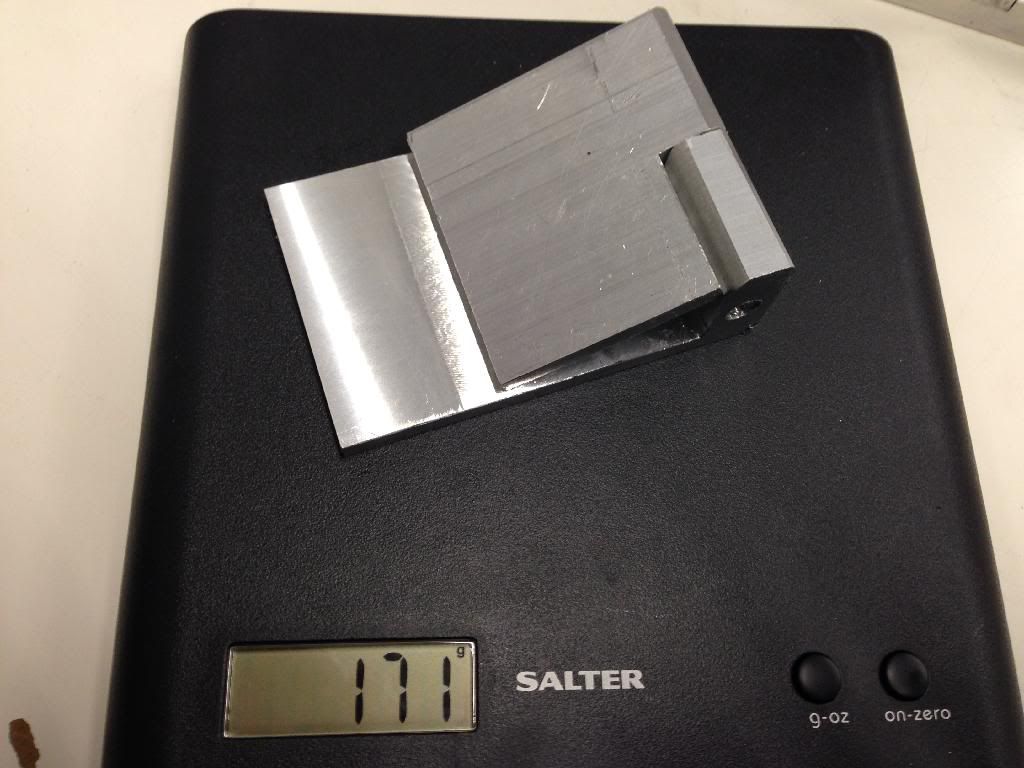

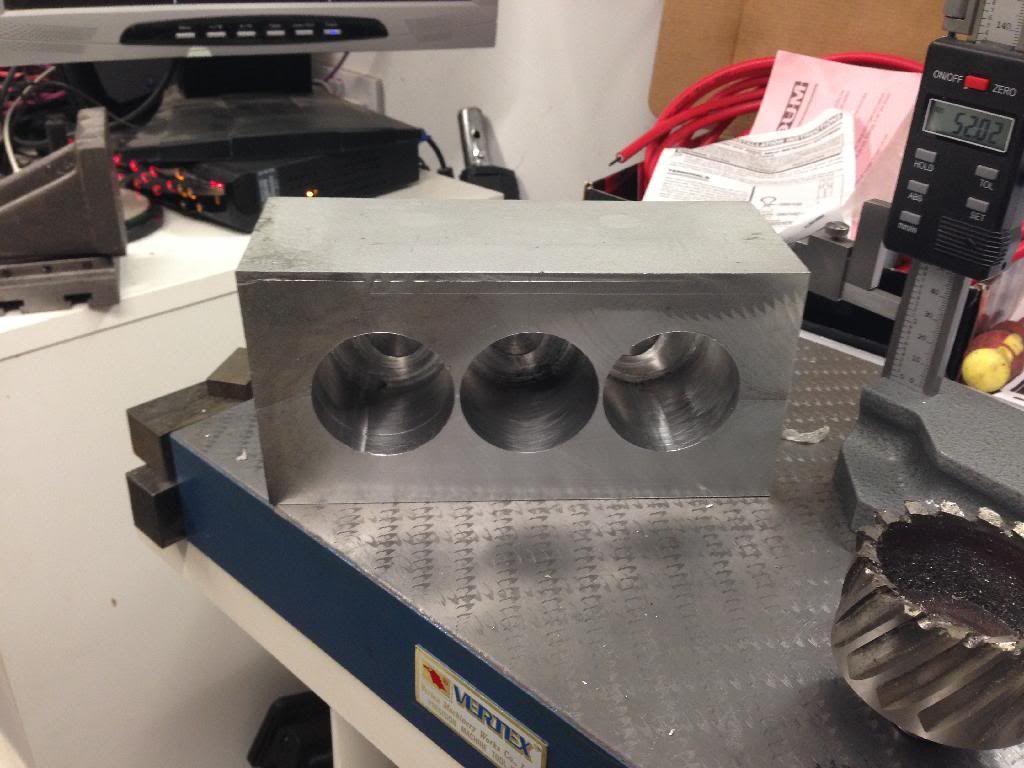

Bit more, been busy at my day job but you can fit a lot in, in 24hrs lol 4x4x8 bit of billet soon to be turned into a brake and clutch resevoir i hope, I think it's going to take at least 14 hours.    Lots of material to remove yet maybe 4x4 was a bit big Cheers Andy |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #743 on: April 26, 2014, 19:24:29 pm » |

|

|

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #744 on: May 11, 2014, 19:51:59 pm » |

|

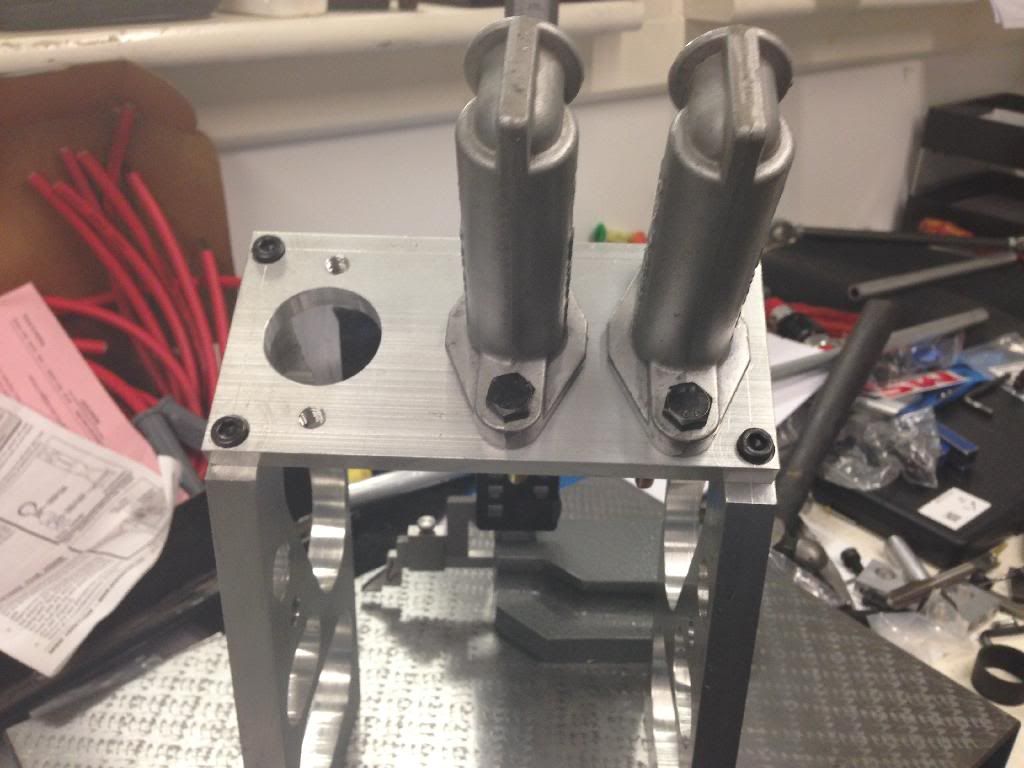

Been busy at the mill so not much going on 4" velocity stacks arrived need cutting and welding but you get the idea  Then brick being leak tested  Towing eye in construction  Cheers Andy |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #745 on: May 15, 2014, 20:14:36 pm » |

|

Bit more on the peddal box   Cheers Andy |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #746 on: May 16, 2014, 22:04:04 pm » |

|

Bit more done today mostly exciting things from America lol  Fuel filter can't get over how big it is those fittings are an12 just shows how much fuel is going to flow  Bit more on the pedal box  Cheers Andy |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #747 on: May 18, 2014, 18:50:43 pm » |

|

|

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #748 on: May 19, 2014, 19:40:58 pm » |

|

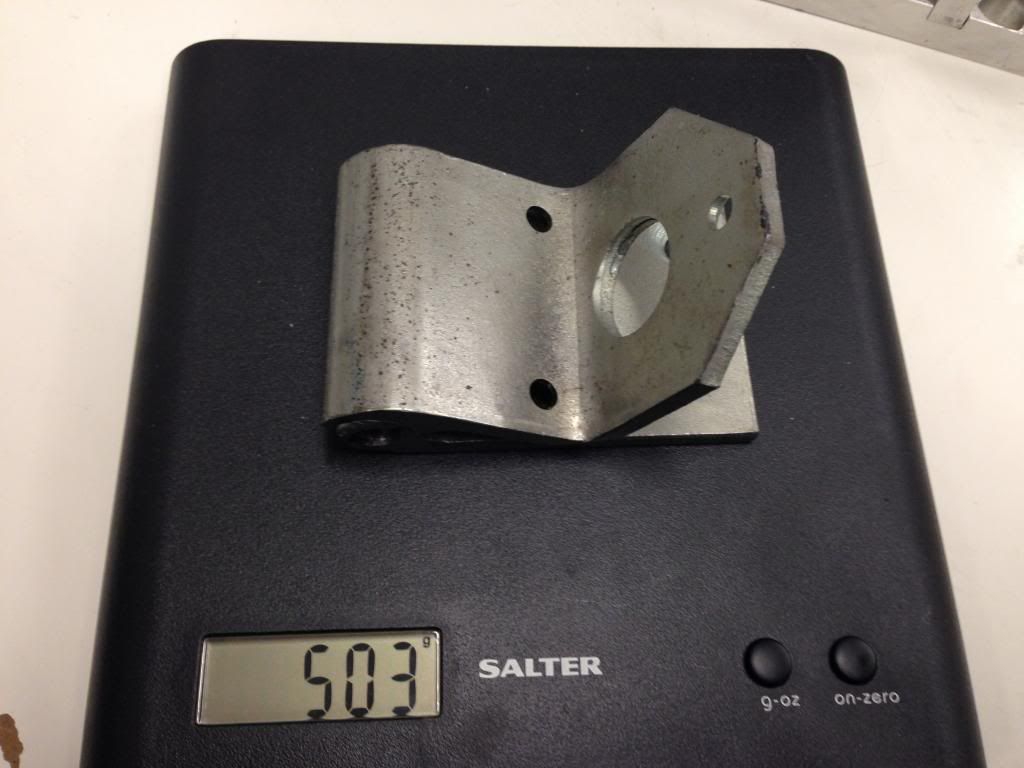

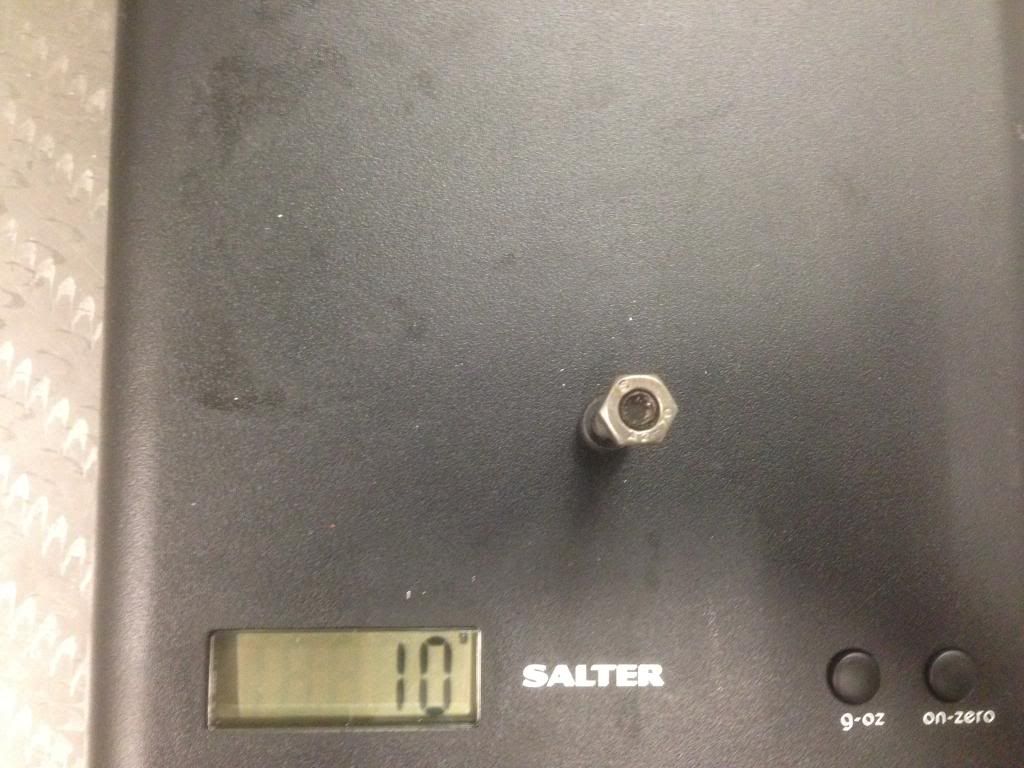

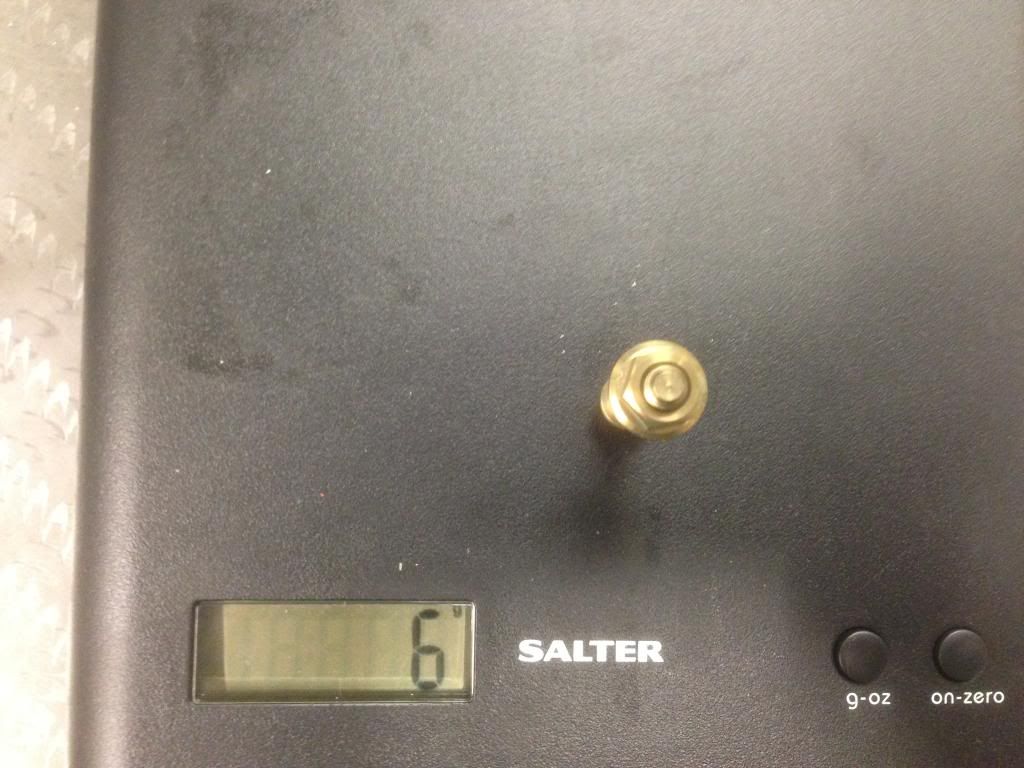

Little bit more Steel m6 nut and bolt  Ti nut and bolt  So a massive 320 grams or 11 ounces saved lol   Last little bit of the peddal box just need a few bits welding up  Cheers Andy |

|

|

|

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

Andy Sykes

|

|

« Reply #749 on: May 21, 2014, 22:28:16 pm » |

|

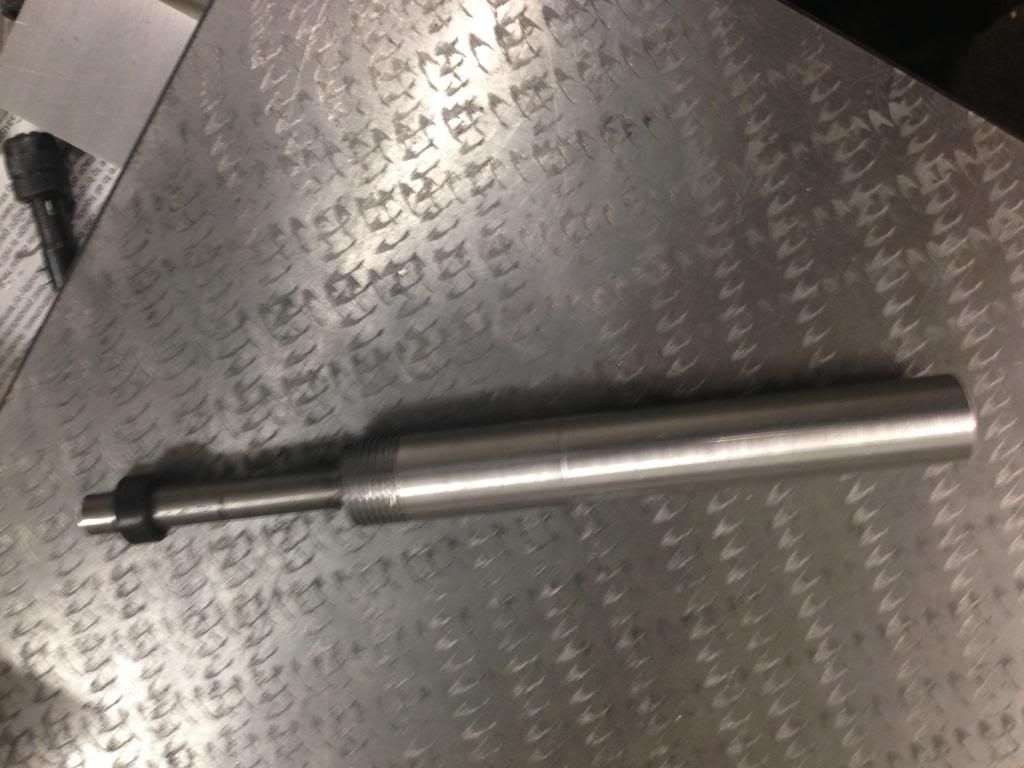

So I decided to make my own hydraulic throttle yes a cable would be easier, but I had the idea so had to make it so lol Cylinder rod and piston    You can only just see but that's the piston  That's one end  Just got to make this end work  And some turbo bits  At least the are the real deal the tial ones I got turned out to be fake, very good fakes but fake lol Cheers Andy |

|

|

|

« Last Edit: May 21, 2014, 22:34:01 pm by Andy Sykes »

|

Logged

Logged

|

I love the haters they make me famous.

im building this not just putting parts together, they are two totally different things

Your only here once turn it up to 11

|

|

|

|

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge

The Cal-look Lounge